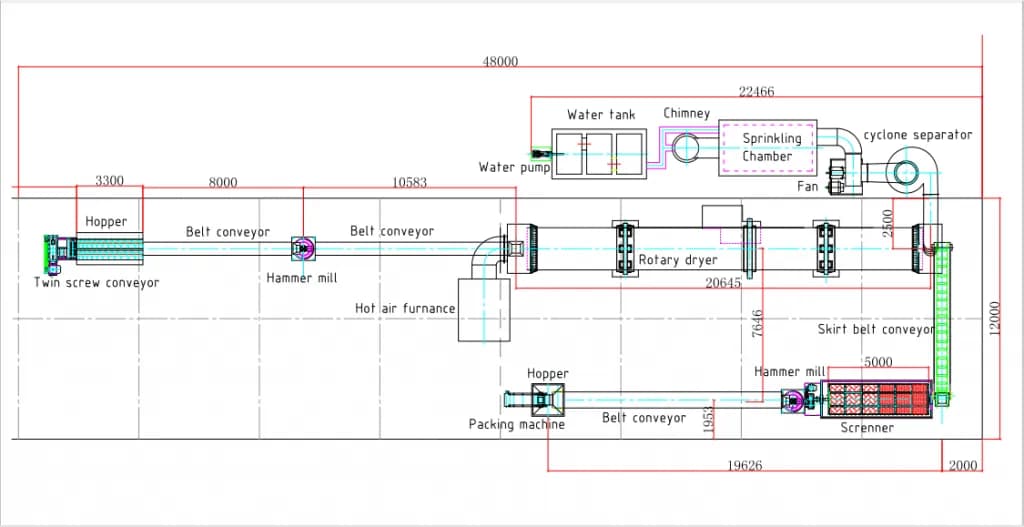

5-6t/h Chicken manure dryer plan in Kenya

The organic fertiliser dryer is suitable for large, medium and small chicken farms and areas where the farming industry is more developed. Different heat sources can be used according to the requirements of the drying products. Such as: gas generating furnace, direct hot air furnace, indirect hot air furnace, heat-conducting oil, electric heating, steam, etc. The machine is suitable for chicken manure, duck manure, livestock manure and slaughter scraps with water content less than 65%, which has good effect on opening up feed resources, reducing feeding costs and reducing environmental pollution.

1、Production process of chicken manure dryer: The machine will dry the fresh chicken manure containing 65% moisture through high temperature drying, sterilization, decomposition and other processes to make pure chicken manure organic fertilizer containing less than 13% moisture.

2、Drying finished product: The organic fertilizer has many kinds of nutrients necessary for crops. It has been tested by the scientific research department and found to contain 2.6% nitrogen, 3.5% phosphorus, 2.5% potassium, 16-25% crude protein and 45% organic matter. It is the choice of fertilizer for pollution-free green food planting, and can also be used to feed fish, cattle, pigs, etc.

3, chicken manure without odour drying mechanization degree is high, production capacity is large, can be continuous operation.

4, excellent structure, simple, material through the cylinder resistance running smoothly, easy to operate.

5、Few faults, low maintenance costs, low power consumption.

6、A wide range of application, good uniformity of product drying.

7, drying can also achieve the purpose of sterilization and deodorization.

Chicken manure dryer is mainly composed of heat source, feeder, feeder, rotary drum, material crushing device, discharger, induced draft fan, unloader and power distribution cabinet; after the wet material is added to the dryer, the material is evenly dispersed and fully contacted with hot air in the chicken manure dryer under the flip of the copier in the drum, which accelerates the heat and mass transfer of drying. In the drying process, the material is discharged from the dryer to the star discharge valve in another section of the dryer under the action of the inclined copying plate and the hot air medium.