Desulfurized gypsum dryer Product Description

At present, the treatment process and equipment of desulfurized gypsum are not completely the same as that of natural gypsum, such as material transportation, dust treatment, calcination process, etc. In terms of physical properties, there are also differences between desulfurized gypsum and natural gypsum, such as high purity, large free water and fine particle size;

The particle size distribution is uniform, the grading is poor, and the water consumption for standard consistency is large. It is also worth noting that the sources of desulfurized gypsum and natural gypsum are different. The quality of desulfurized gypsum will be affected by the presence of unreacted calcium carbonate as the main impurity and calcium sulfite that has not been completely oxidized, the composition of limestone raw materials, and the fineness of processed limestone.

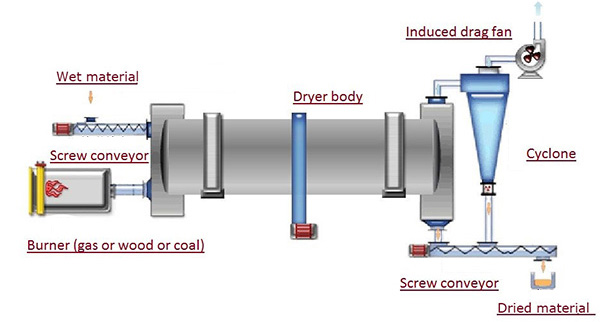

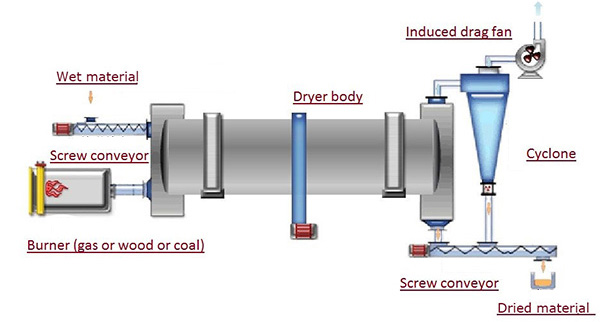

Desulfurized gypsum dryer Working Principle

The desulfurized gypsum enters the inner layer of the multi-layer drum from the feeding device to realize the forward flow drying. The desulfurized gypsum is continuously lifted and scattered under the board of the inner layer to realize the heat exchange in a spiral way. The materials move to the other end of the inner layer and enter the middle layer for countercurrent drying. The materials are repeatedly lifted in the middle layer, in a two-step and one-step traveling mode.

The materials not only fully absorb the heat emitted by the inner layer drum in the middle layer, It also absorbs the heat of the middle drum, and at the same time extends the drying time, so that the material reaches a dry state here. The materials go to the other end of the middle layer and fall into the outer layer.

The materials travel in a rectangular multi loop manner in the outer layer drum. The materials that achieve the drying effect travel quickly and are discharged from the drum under the action of hot air. The wet materials that do not achieve the drying effect cannot travel quickly due to their own weight. The materials are fully dried in this rectangular sheet, so as to achieve the drying effect and complete the drying process.

Desulfurized gypsum dryer Features And Advantages

1. The advanced manufacturing concept is adopted, which makes the equipment compact and the device occupies a small area.

2. It adopts computer automatic control, which can realize remote control and is easy to operate. According to the drying requirements, different drying temperatures and drying times can be configured to realize drying automation.

3. The material runs smoothly through the resistance of the cylinder, is easy to operate, has few faults, low maintenance costs and low power consumption.

Desulfurized gypsum dryer Technical Parameter

Model(m)

| Volume

(m³) | throughput

(t/h) | slope

(%) | air temperature

(℃) | motor

(kw) | weight

(t) |

| Φ1.2×8.0 | 9.0 | 1.9-2.4 | 3-5 | 700-800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4-3.0 | 3-5 | 700-800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5-5.7 | 3-5 | 700-800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3-6.6 | 3-5 | 700-800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7-7.1 | 3-5 | 700-800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5-8.1 | 3-5 | 700-800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6-9.5 | 3-5 | 700-800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7-12.2 | 3-5 | 700-800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4-14.2 | 3-5 | 700-800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0-16.2 | 3-5 | 700-800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5-16.9 | 3-5 | 700-800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4-21.7 | 3-5 | 700-800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3-24.1 | 3-5 | 700-800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2-26.5 | 3-5 | 700-800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2-34.0 | 3-5 | 700-800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1-37.7 | 3-5 | 700-800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7-47.1 | 3-5 | 700-800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9-53.6 | 3-5 | 700-800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8-76.0 | 3-5 | 700-800 | 160 | 135 |