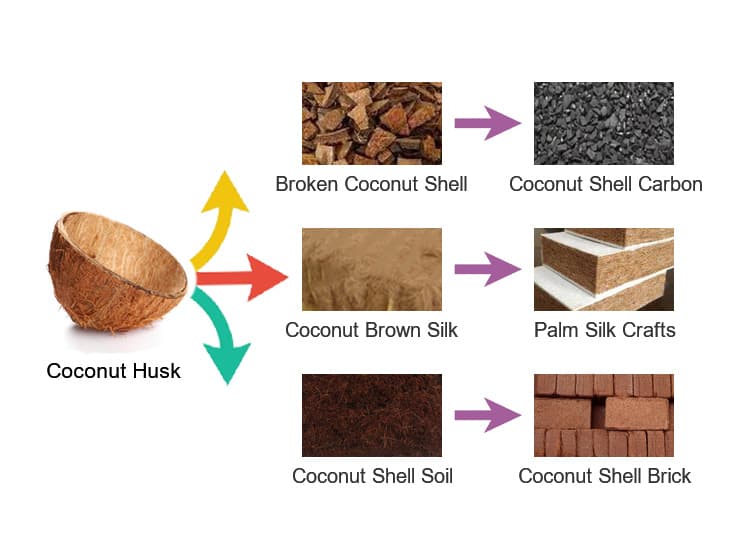

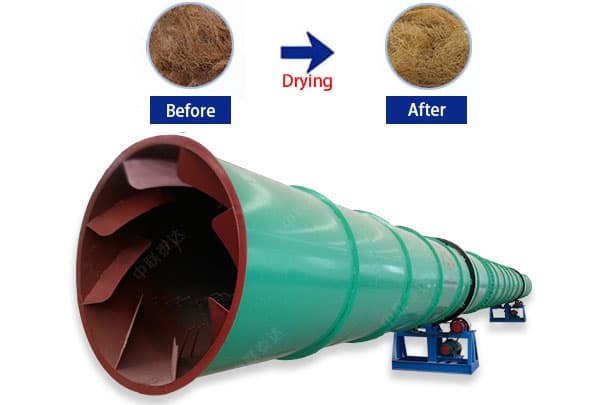

Coconut Coir Dryer Product Description

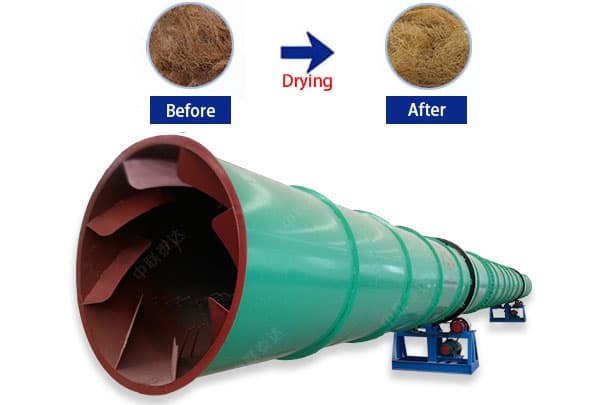

Coconut fibre, coir fibre, has unique properties such as being moth-proof, anti-bacterial and non-decaying. It is traditionally used as a raw material for mattresses and seat cushions and is highly prized in the market. Coir fibre is sifted from coconut shells and has a moisture content of approximately 30%. Traditional drying methods tend to discolour and mould the coir, which affects the quality.

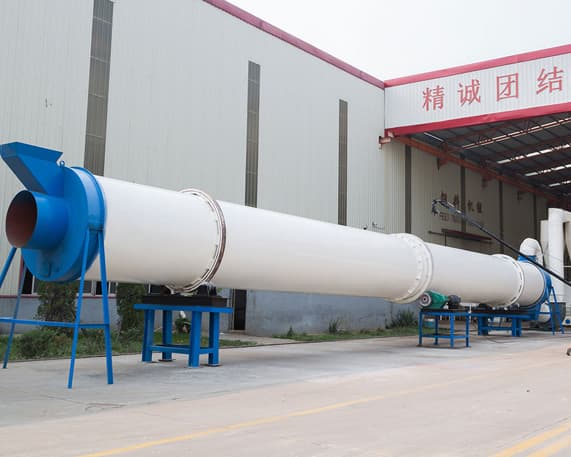

ZOOMJO Group has developed the special drying machine for coconut coir, coconut fiber drying production line, which can be directly connected to the coir opener, coir sorting, desalination, dewatering and drying, and the drying process of coir fibre can be completed within 40 minutes. Pipeline operation, energy saving, labour saving and environmental protection, the quality of coconut palm and fibre can be guaranteed to the maximum extent, and the high temperature treated coconut palm and fibre are cleaner and more environmental friendly. This production line is the necessary equipment to realise the mechanisation, scale and intensive production of coconut palm and fibre.

In the scheme design of the special drying machine for coconut palm, the characteristics of coconut palm fibre which is flammable, easy to clump and wrapped by the chaff layer are fully considered, and a series of original and unique technologies and techniques are adopted to solve this problem, ensuring good drying effect and cleanliness of coconut palm fibre.

After desalination and dehydration, 50-60% moisture coconut husk enters the dryer to realise flow drying, coconut husk is continuously lifted on the shovel plate inside the dryer, spiral forward, through the inner, middle and outer layer of the dryer, coconut husk is heat exchanged with hot air, the dried coconut husk moves quickly and is discharged under the action of wind, wet coconut husk cannot move quickly due to its own weight. The coconut husk is fully dried in the dryer and the moisture is reduced to 14-18% (can be adjusted according to the customer's requirements), after the drying process the husk will be discharged by the screw conveyor. A special device inside the dryer prevents uneven drying of the coconut husk.

Coconut Coir Dryer Working Principle

Coconut Coir dryer is mainly composed of hot air furnace, feeding conveyor, rotary dryer, discharging conveyor, dust collector, power distribution cabinet and so on. After the sorted coconut shell fiber enters the dryer, under the action of the evenly distributed tooth-shaped stirring device in the drum, the material is evenly dispersed, in full contact with the hot air, quickly transferring heat, mass and drying, and discharged to the discharge port of the drum. The whole production line includes coconut shell splitting machine, coconut shell drying machine, coconut shell sorting equipment, desalination equipment, dewatering machine, drying machine and so on. The whole set of assembly line operation, saving work and time, energy saving and environmental protection, is the first choice of equipment for coconut palm processing enterprises.

After the coconut palm is dewatered by the dewatering machine (if the moisture content is high), it is then conveyed to the drum dryer by the belt conveyor. Due to the inclination of the drum dryer, the material with hot air moves to the end of the main body of the dryer, where the wet material comes into full contact with the hot air in the process. After drying, most of the dried material is discharged via the belt conveyor. The remaining material is mixed with dust and continues in turn to the cyclone and baghouse where the dust will be collected. Finally, the remaining material will be discharged via the conveyor under the action of the induced draft fan.

Coconut Coir Dryer Features And Advantages

1. Automatic control ensures a homogeneous and stable drying process.

2. Internal structure designed for coconut peat. Drying efficiency of up to 90-95%.

3. Customised solutions. Variation of the operating parameters according to the properties of the required parameters.

4. Designed lifting plates. Various materials are lifted using various combinations of circles.

5. System equipped with PLC system and video monitoring system for high automation and easy operation.

6. Multiple heating sources. The customer can choose the heating source according to his situation and we can design customised solutions.

Coconut Coir Dryer Technical Parameter

|

Item | ZJ25-A |

ZJ25-B |

ZJ30-A |

ZJ30-B |

ZJ30-C |

ZJ36-A |

ZJ36-B |

ZJ36-C |

ZJ42-A |

ZJ42-B |

|

Diameter (mm) |

2500 |

2500 |

3000 |

3000 |

3000 |

3600 |

3600 |

3600 |

4200 |

4200 |

|

Length (mm) |

8000 |

10500 |

10500 |

13000 |

15500 |

13000 |

15500 |

18500 |

15500 |

18500 |

|

Capacity (t/h) |

2 |

3 |

4.5 |

5.5 |

6.5 |

9 |

10 |

12 |

13.5 |

16.8 |

|

Drying Type |

Three pass drum dryer |

|

Note |

Proper models can be customized according to your demands. Please feel free to contact with us any time! |