Sawdust dryer Product Description

The sawdust dryer manufactured by our company adopts three-ring rotary dryer, which greatly improves the drying capacity through the way of downstream heating. The wood chip dryer has the characteristics of simple structure, large processing capacity, high thermal efficiency, easy maintenance, low cost and so on. It is widely used in the drying of wood chips, sawdust, wood flour, wood chips, shavings, corn straw, soybean straw, sorghum straw and other biomass fuels.

Sawdust dryer Working Principle

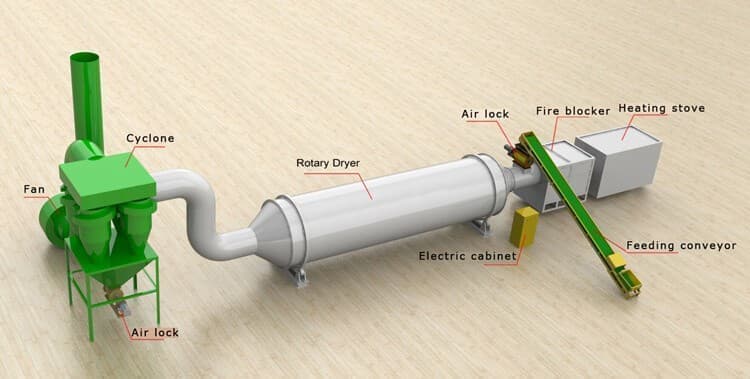

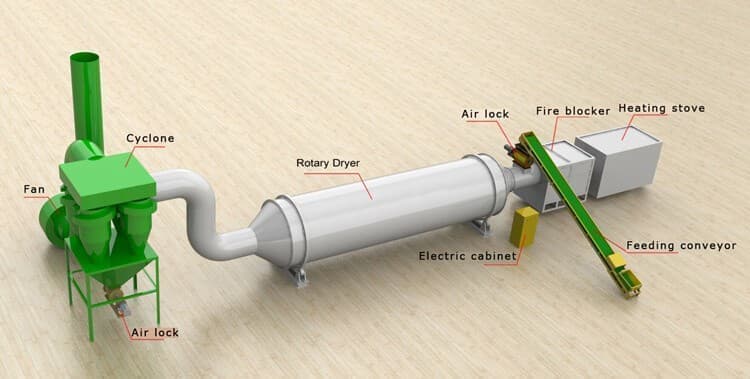

The structure of the sawdust dryer includes a heating furnace, a feeding port, a rotating cylinder, a filter cylinder, a material conveying pipe, a cooling cylinder and a discharging port. The saw dust is fully dried in the rotating cylinder, and the saw dust is fully dispersed again before entering the material conveying pipe, so that the moisture evaporates quickly.

The stopper can block the impurities in the saw dust and ensure the quality of the saw dust entering the material conveying pipe. Wood chips enter the dryer, the materials boil and fluidize in the cylinder, and the hot air fully contacts the materials to complete the drying.

Sawdust dryer Features And Advantages

1. Low energy consumption

The dryer of our factory selects reasonable operating parameters, and the coal consumption and power consumption are reduced by more than 10-15% compared with ordinary dryers.

2. High thermal efficiency

The downstream drying method is adopted. The material and heat source air flow enter the drying equipment from the same side. The outlet temperature of the dryer is low and the thermal efficiency is high.

3. Large processing capacity and small floor area

The air dryer has simple structure, small floor area and is easy to build and maintain. Large processing capacity and high thermal efficiency.

4. Simple structure and convenient operation

The utility model has the advantages of excellent structure, simple structure, stable operation of materials through the resistance of the cylinder, and convenient operation.

Sawdust dryer Technical Parameter

Specificationsm)

| volume

(m³) | throughput

(t/h) | Installation slope

(%) | air temperature

(℃) | Main motor

(kw) | weight

(t) |

| Φ1.2×8.0 | 9.0 | 1.9-2.4 | 3-5 | 700-800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4-3.0 | 3-5 | 700-800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5-5.7 | 3-5 | 700-800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3-6.6 | 3-5 | 700-800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7-7.1 | 3-5 | 700-800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5-8.1 | 3-5 | 700-800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6-9.5 | 3-5 | 700-800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7-12.2 | 3-5 | 700-800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4-14.2 | 3-5 | 700-800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0-16.2 | 3-5 | 700-800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5-16.9 | 3-5 | 700-800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4-21.7 | 3-5 | 700-800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3-24.1 | 3-5 | 700-800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2-26.5 | 3-5 | 700-800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2-34.0 | 3-5 | 700-800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1-37.7 | 3-5 | 700-800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7-47.1 | 3-5 | 700-800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9-53.6 | 3-5 | 700-800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8-76.0 | 3-5 | 700-800 | 160 | 135 |