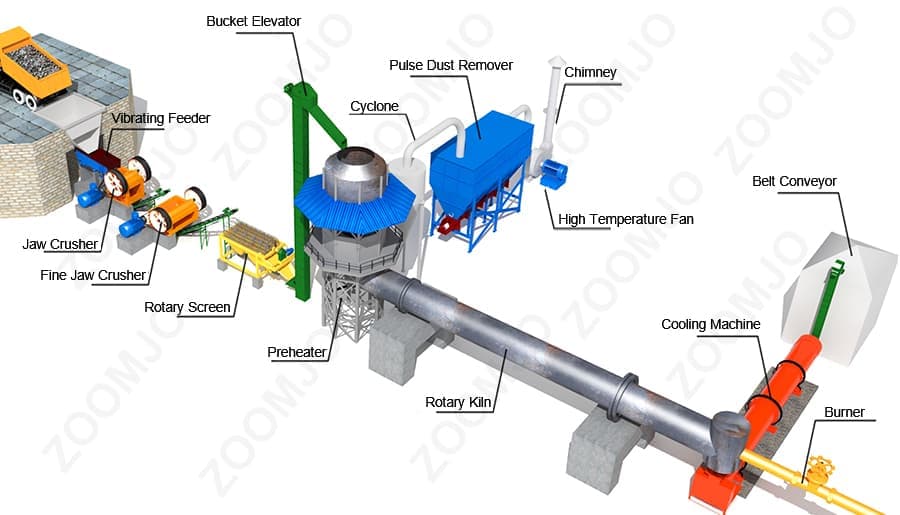

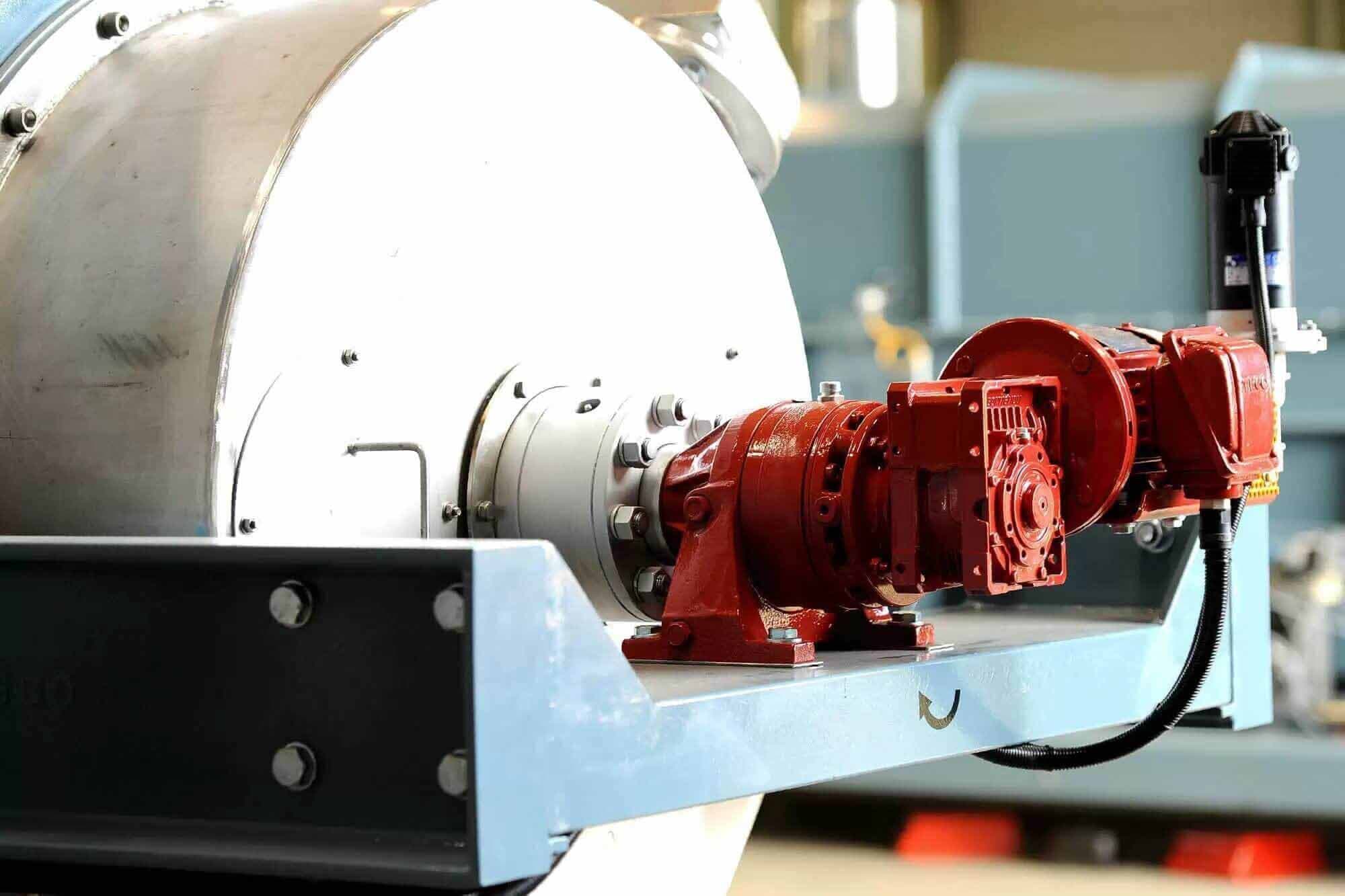

Brown iron ore roasting rotary kiln refers to rotary calcining kiln (commonly known as rotary kiln). The structure of lignite rotary kiln is simple, the production process control is convenient and reliable, there are few wearing parts, and the operation rate is high. The limonite rotary kiln produced by our factory has a sturdy structure, smooth operation and high quality of the kiln output, and can provide customers with vertical preheater and five-stage cyclone preheater. The kiln head hood of limonite rotary kiln adopts the large volume method and the structure of opposite kiln door, which makes the air flow more smoothly. The kiln head and kiln tail seal adopt the double sealing forms of radial friction labyrinth and fish scale piece, with simple structure and convenient maintenance.

Performance characteristics of limonite rotary kiln:

Brown iron ore rotary kiln is used in mineral processing, building materials, metallurgy, chemical industry and other sectors to dry certain humidity or size of materials. The rotary kiln has a strong adaptability to materials, can dry a variety of materials, and the equipment is simple and reliable operation, so it is commonly used.

Fuel used in rotary kilns for calcining limonite.

According to its state, it can be divided into: 1, solid fuel, such as coal, coke, etc.; 2, liquid fuel, such as heavy oil, paraffin, diesel fuel, etc.; 3, gas fuel, such as liquefied petroleum gas, coal gas from the furnace, natural gas, etc.