Metallurgical rotary kiln project in Cambodia

Metallurgy is the basis of national economic construction and is a sign of the country's strength and level of industrial development. It provides the material products required by various industries such as machinery, energy, chemical industry, transportation, construction, aerospace industry and defence industry.

After visiting several rotary kiln plants, the customer from Cambodia finally signed a cooperation agreement with our company because of the simple structure of our new metallurgical rotary kiln, easy and reliable control of the production process, low wearing parts, high operation rate and high quality of the kiln output.

Our metallurgical rotary kiln has the following advantages.

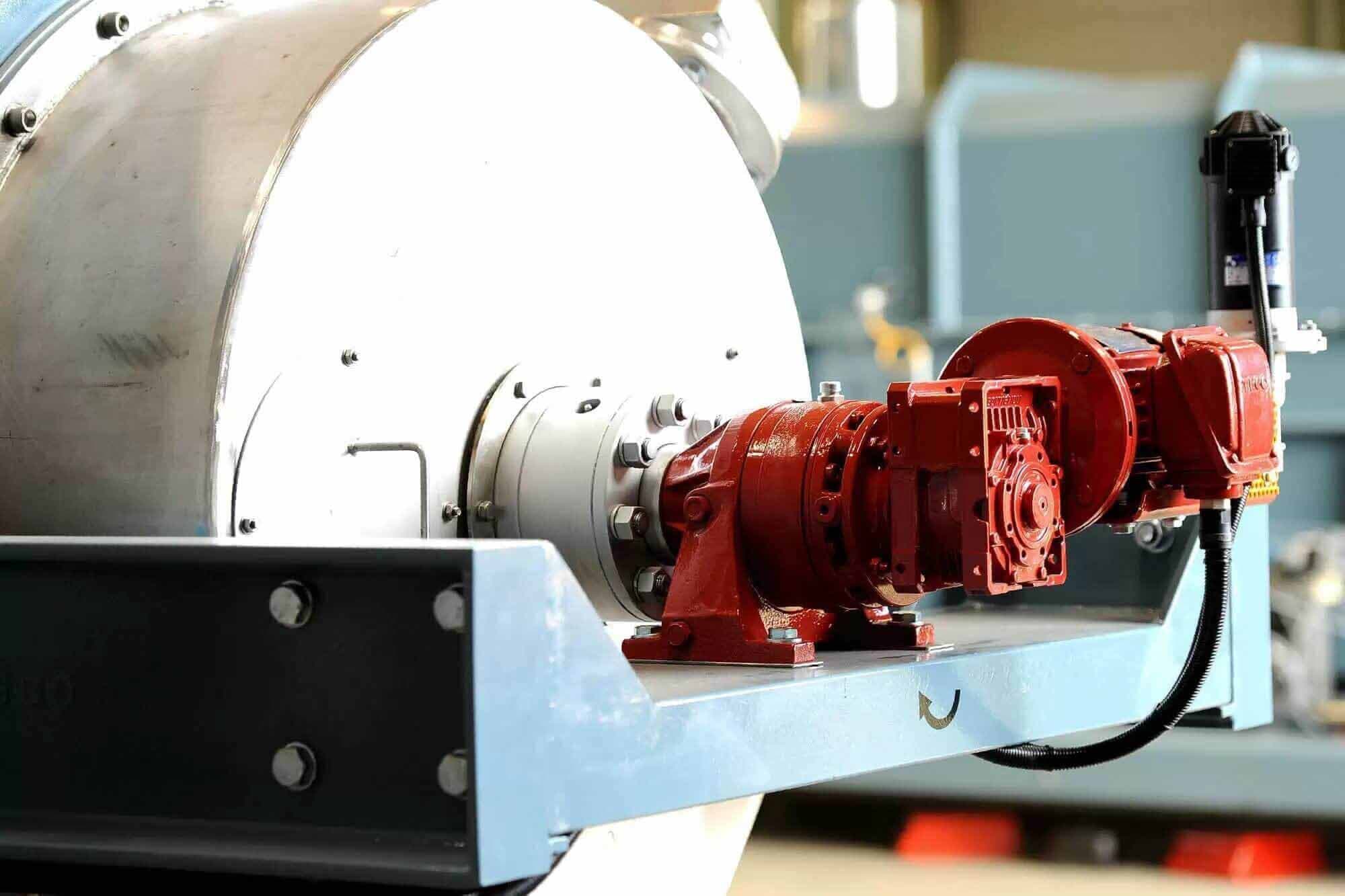

1、Rotary kiln's consist of cylinder, supporting device, transmission device, kiln tail and kiln head seal.

2. The length-to-diameter ratio of the rotary kiln is reduced from the traditional 20-25 to 14-15, reducing the heat dissipated from the surface of the rotary kiln to the surrounding area.

3、The transmission system adopts frequency-controlled motor, equipped with frequency converter, which has the advantages of large speed range and heavy load starting.

4、The kiln head and kiln tail use heat-resistant steel scale seal to replace the original seal, which not only reduces the amount of air leakage from the kiln head and kiln tail, but also is durable.

Fuel used in metallurgical rotary kiln.

According to its state, it can be divided into: 1. solid fuels, such as coal, coke, etc.; 2. liquid fuels, such as heavy oil, paraffin, diesel, etc.; 3. gas fuels, such as liquefied petroleum gas, coal gas from the furnace, natural gas, etc.

The working principle of metallurgical rotary kiln:

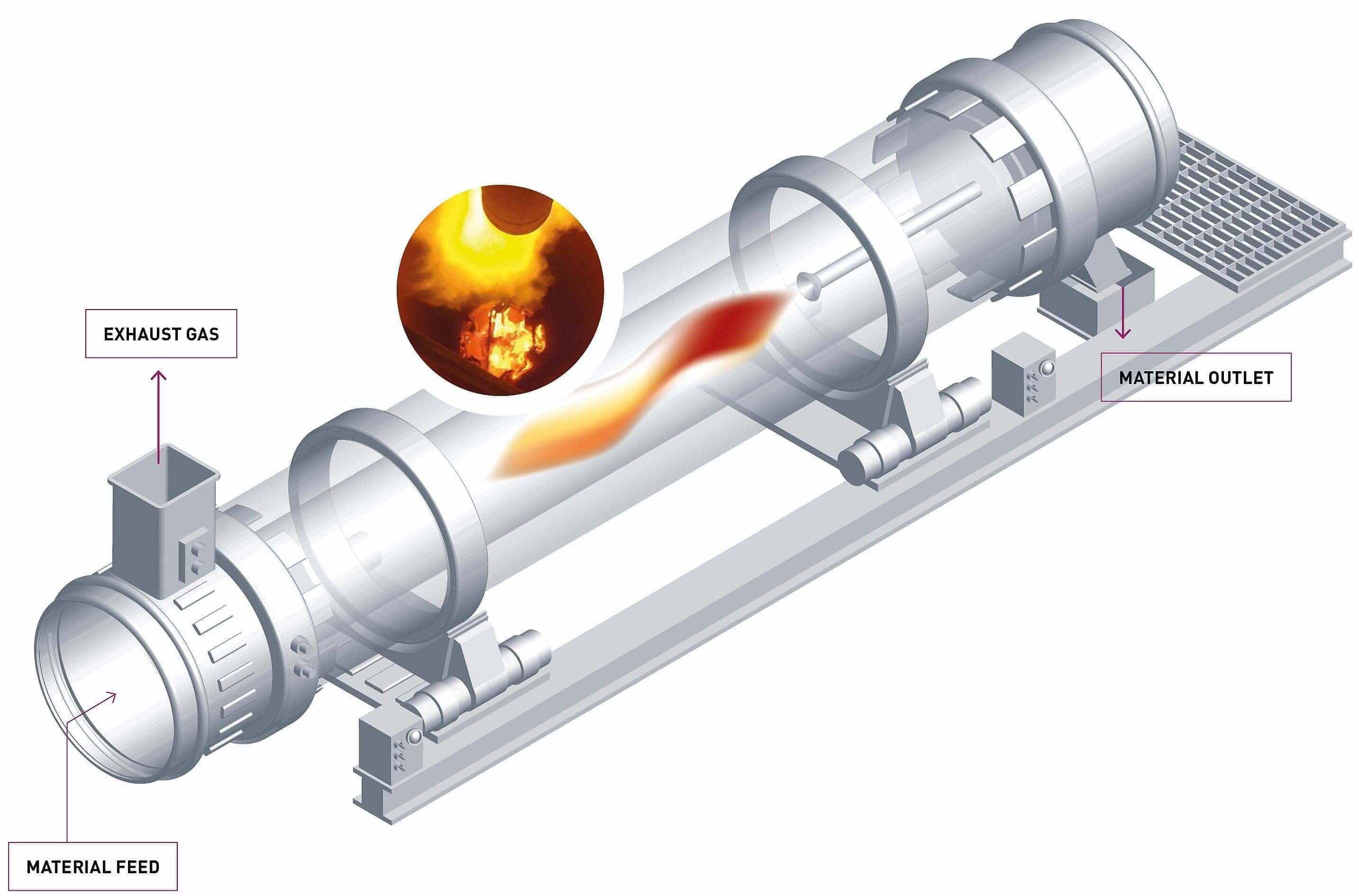

When the metallurgical rotary kiln is in normal operation, the main drive motor transmits power to the open gear device through the main reducer to drive the rotary kiln. The material enters the kiln from the end of the kiln (the top end of the cylinder) and is calcined. Due to the tilting and slow rotation of the cylinder, the material both rolls in a circular direction and moves axially (from the high end to the low end) to produce clinker that is cooled by the kiln head hood into the cooler. The fuel is sprayed into the kiln from the kiln head and the exhaust gases from the combustion are exchanged with the material and then exported from the kiln tail.

ZOOMJO group is a professional manufacturer of rotary kilns in China, we can also supply various models of rotary kilns to our customers according to their needs. We also provide professional engineers to install the equipment and provide the best service.