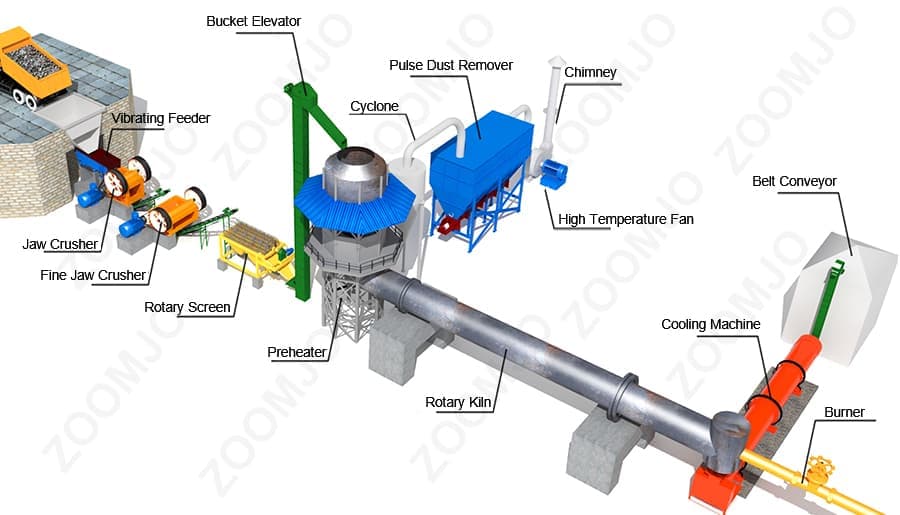

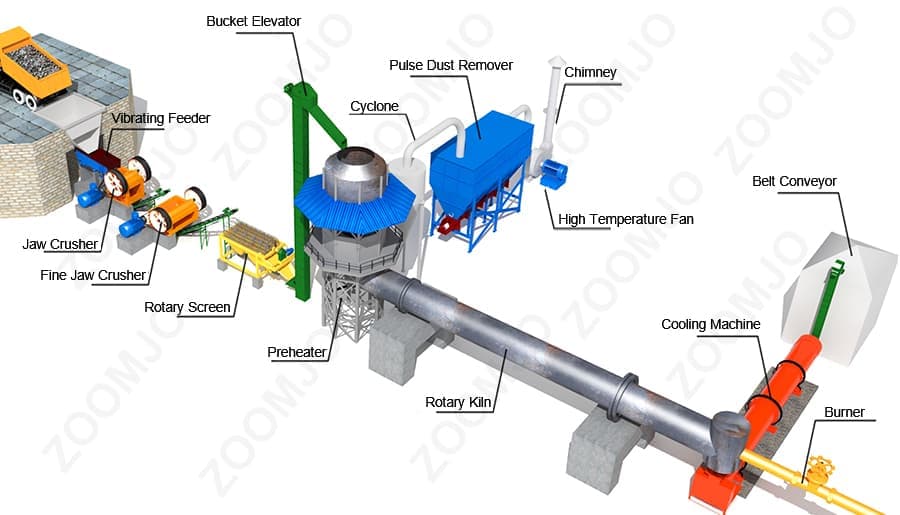

Cement Rotary Kiln Product Description

Cement rotary kilns are mainly used for calcining cement clinker and are divided into two main categories: dry process cement kilns and wet process cement kilns.

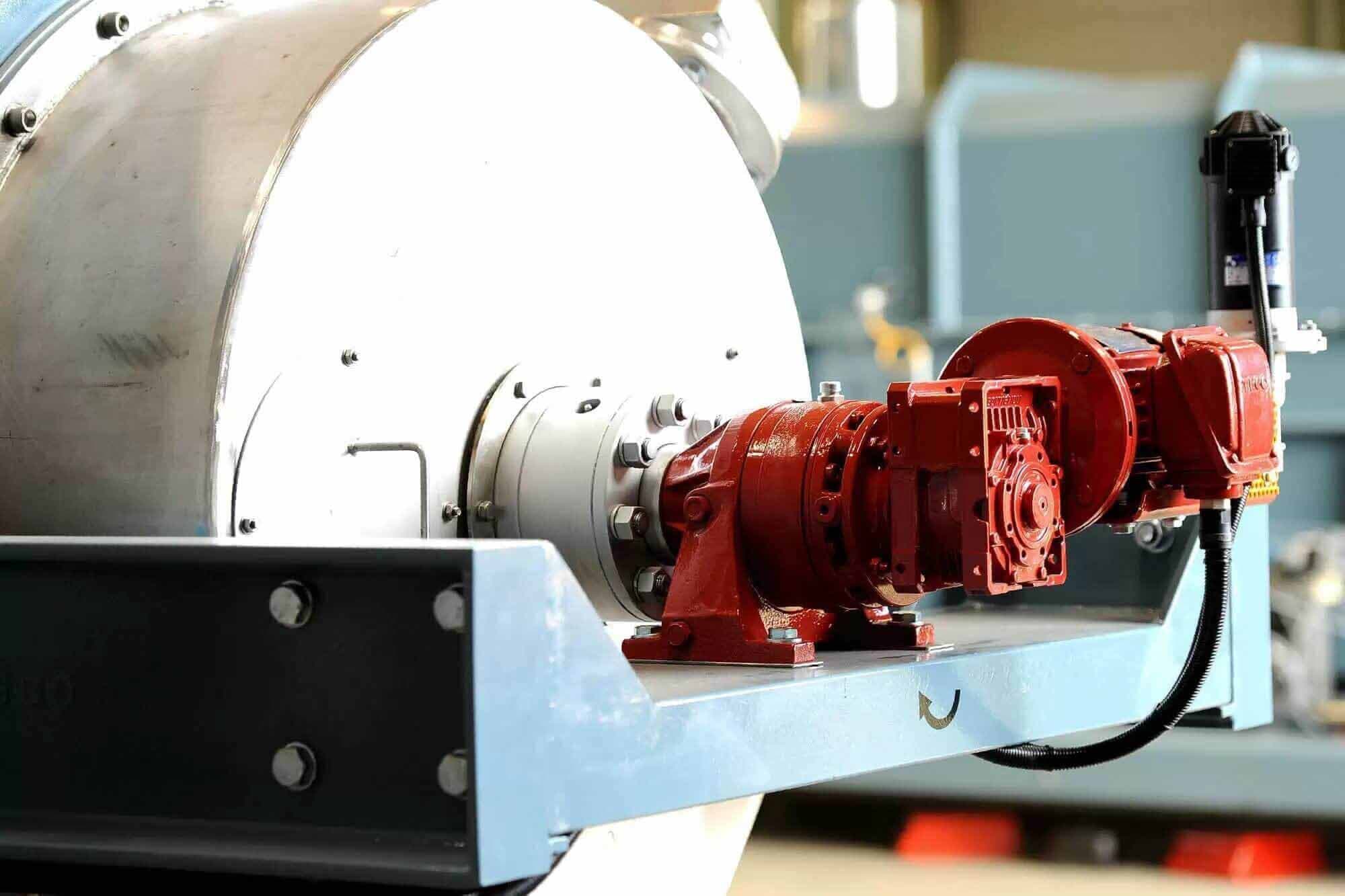

The cement rotary kiln consists of a cylinder, a supporting device, a supporting device with a retaining wheel, a transmission device, a movable kiln head, a sealing device at the end of the kiln and a coal spray pipe device.

In addition to the main drive, the transmission system is also equipped with an auxiliary drive device that can make the kiln rotate and prevent the kiln from bending and deforming when the main power source is broken.

Cement Rotary Kiln Working Principle

1、The raw ore is fed directly into the kiln end of the rotary kiln from the storage through the electronic belt weighing scale, belt conveyor, stabilizer bin and air lock valve, and only a stabilizer bin is set up at the end of the kiln to reduce investment.

2、Ore entering the rotary kiln is firstly heated, the raw ore moves in the reverse direction with the hot air flow in the kiln, in the heating zone the raw ore is heated to the reduction temperature and then enters the reduction zone.

3, the reduction zone flame centre temperature control at about 1000 ℃, the reduction zone hot atmosphere temperature control 700 ℃ or so with the reduction of gas reaction reduction into magnetite.

4、Afterwards, it enters the cooling zone and meets with the incoming gas, the gas is preheated and the ore is cooled and discharged from the kiln, after being water-cooled by the continuous bucket conveyor, it is put into storage for selection.

Cement Rotary Kiln Features And Advantages

1. Stable function, low energy consumption, high output, easy to operate. Rotary kiln’s structure is simple, production process control conveniently and reliably and it is less wearing parts and high operation rate.

2. One hand,rotary kiln is the combustion equipment,in which coal powder burns to produce heat;Another hand, rotary kiln is the heat transfer equipment,raw materials absorb the gas heat to burn. Fuel combustion, heat transfer and material movement must be reasonable co-ordination to make the heat produced by material burn transfer to raw material timely when raw material go through the rotary kiln.This can reach the high-yield, high-quality and low consumption of purpose.

3. The rotary kiln firing system is equipmented with technological innovation,This system adopts the domestic advanced technology,such as the most advanced hydraulic block wheel device, a high measurement accuracy of measurement piston pump, high-precision control valve and contact-type graphite block sealing device.

4. Easy to operate, reliable use. Stabilize the thermal system, and improve the equipment operation rate, increase 10% operation rate compared with the same specifications equipment, production increased by 5% -10%, reduction 15% heat loss.

Cement Rotary Kiln Technical Parameter

| Specification(meter) | φ2.8/2.5×44 | φ3×48 | φ3.2×50 | φ3.3×50 | φ3.5×54 | φ4×60 | φ4.3×64 | φ4.8×74 | φ5.0×74 |

| Production(t/d) | 300 | 600-700 | 1000 | 1200 | 1500-1800 | 2500 | 3500 | 5000 | 6000 |

| rake of Kiln(%) | 3.5 | 3.5 | 3.5 | 4 | 4 | 4 | 4 | 4 | 4 |

| Number of bearing (Number) | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| Block wheel form | Machinary | Mechinary or Hydraulic pressure | Hydraulic pressure | Hydraulic pressure | Hydraulic pressure | Hydraulic pressure | Hydraulic pressure | Hydraulic pressure | Hydraulic pressure |

| | Main transmission (turn/points) | 0.445-2.22 | 0.676-3.38 | 0.36-3.57 | 0.36-3.57 | 0.39-3.9 | 0.41-4.07 | 0.4-4.0 | 0.35-4 | 0.35-4 |

| Auxiliary transmission (turn/points) | 4.75 | 9.36 | 6.5 | 5.61 | 7.66 | 8.2 | 7.93 | 8.52 | 7.58 |

| Main transmission | Electromotor | Model | ZSN4-225-21 | Z2-101 | ZSN4-280-191B | ZSN4-280-191B | ZSN4-315-092 | ZSN4-355-092 | ZSN4-355-12 | ZSN4-450-092Lp44 | ZSN4-450-092 |

| Rated power (kw) | 55 | 100 | 160 | 160 | 220 | 315 | 400 | 630 | 710 |

| Speed range (turn/points) | ~1000 | ~1500 | 1500 | 1500 | 1000 | 1000 | 100-1000 | 1500 | 87.5~1000 |

| Rated voltage (v) | 440 | 220 | 440 | 440 | 440 | 440 | 440 | 660 | 600 |

| Speed reducer | Model | ZS145-1-1 | ZS145-1-1 | ZSY-450-40-V | ZSY450-40 | NZS995-28VIBL | YNS1110-22.4VBR | YNS1400-3105VIBL | JH710C-SW305-40 | JH280C-45 |

| Total ratio | 49-63 | 50 | 40 | 40 | 28 | 22.4 | 31.5 | 42.226 | 28 |

| Auxiliary turn | Electromotor | Model | Y122M-4 | Y160M-6 | Y160M-4B | Y160M-4 | Y200L1-6 | Y180L-4 | Y200L-4 | Y225M-4 lp44 | Y250M-4 |

| Rated power (kw) | 4 | 7.5 | 15 | 11 | 18.5 | 22 | 30 | 55 | 55 |

| The rated speed (turn/points) | 1440 | 970 | 1460 | 1460 | 970 | 1470 | 1470 | 1480 | 1480 |

| Rated voltage (v) | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 |

| Speed reducer | Model | ZL35-16 | ZL35-7-1 | ZSY160-31.5 ‖ | ZSY355-31.5 | ZSY355 | YNS440-45‖R | YNS497-45ZC | JH220C-SW302-28 | JH280C-45 |

| Total ratio | 40.44 | 14 | 31.5 | 31.5 | 45 | 45 | 45 | 28 | 45 |

| The total weight (not including refractory bricks) (tons) | 177 | 213 | 280.6 | 317 | 341 | 434 | 562 | 854 | 885 |