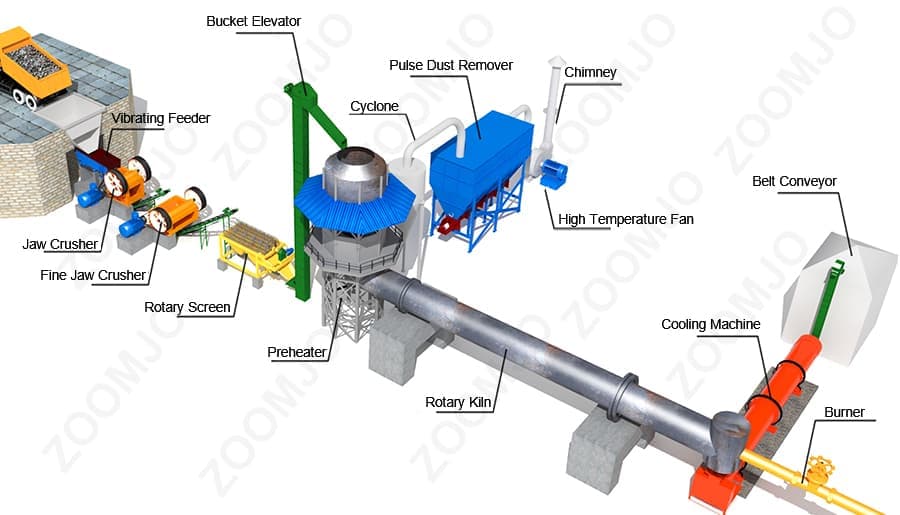

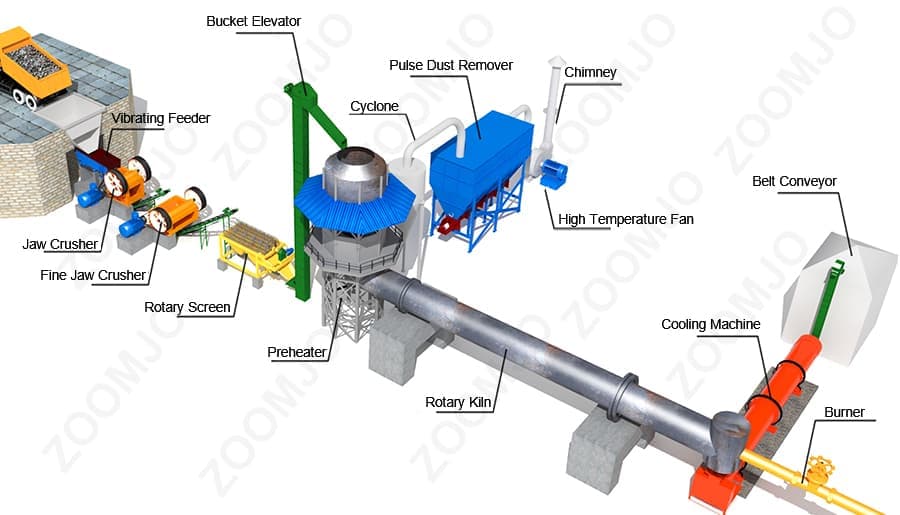

Zinc Oxide Rotary Kiln Product Description

The zinc oxide rotary kiln crushes zinc furnace material and coking coal into granular material of less than 40 mesh, mixes the zinc furnace material and coking coal in the ratio of 1:0.30 to 0.35 to obtain the mixture, then makes the mixture into granular mixture with an effective diameter of 8-15 mm, and then puts the granular mixture into the rotary kiln for smelting.

It has the advantage of saving coke or coal substantially when smelting zinc oxide ore or zinc-containing industrial slag with a zinc content of 15% to 25%; the product quality obtained from smelting is good and the productivity is increased with a small amount of nodules.

Zinc Oxide Rotary Kiln Working Principle

1, zinc oxide rotary kiln with advanced structure, low pressure loss of the vertical preheater can effectively improve the preheating effect, after preheating the decomposition rate of magnesium metal into the kiln can reach 20-25%, and can directly use 10-15mm fine-grained limestone;

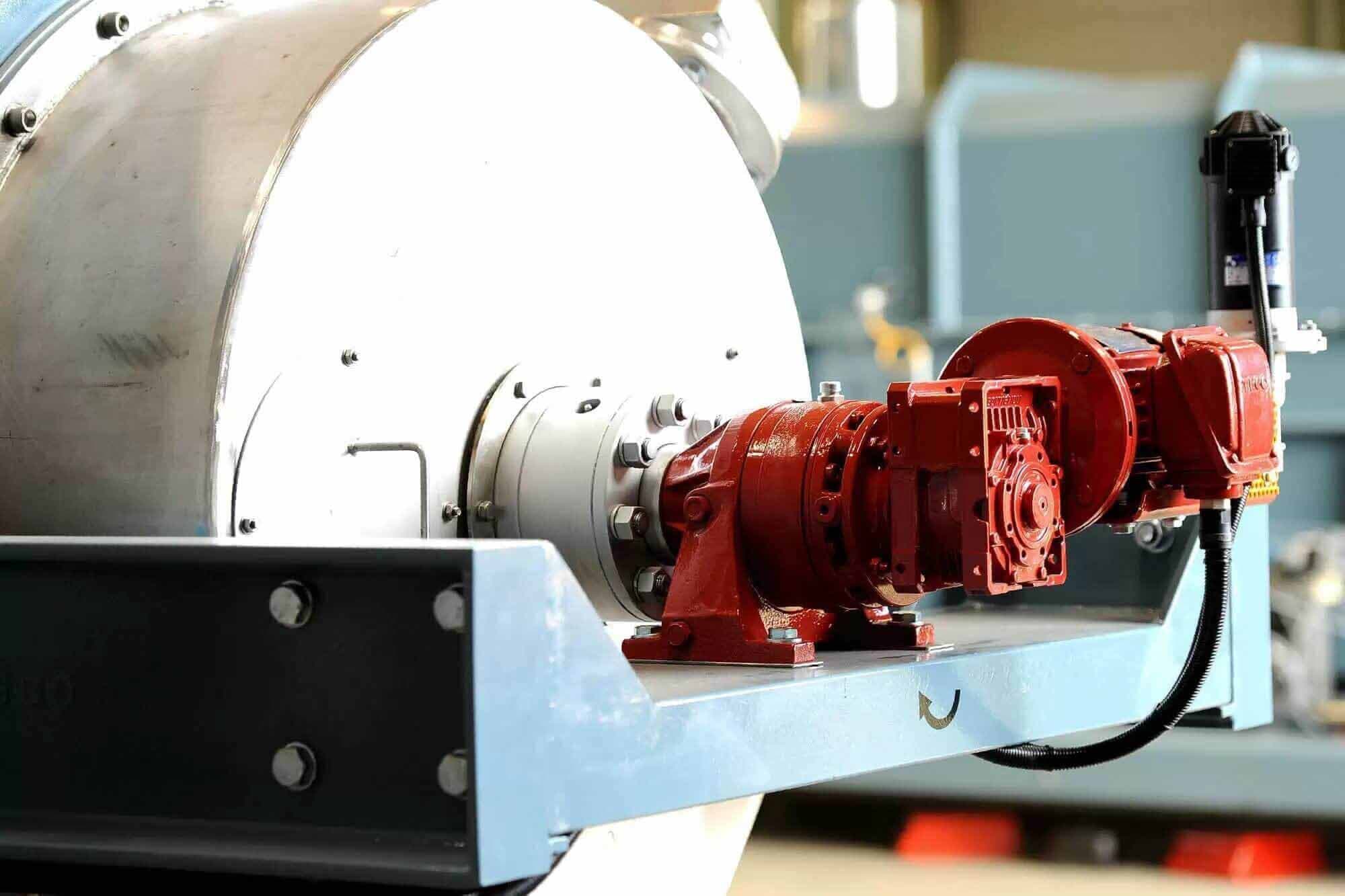

2, zinc oxide rotary kiln reliable rotary kiln at both ends of the combined scale seal. Make the air leakage coefficient less than 10% using composite refractory materials to reduce radiation heat loss.

3, Filled, zone-ventilated round or square vertical cooler, so that the lime temperature out of the cooler is 80°C + ambient temperature, easy to transport and store, and the secondary air into the kiln can be preheated to more than 700°C, reducing moving parts and special materials.

Zinc Oxide Rotary Kiln Features And Advantages

1. After adding the zinc oxide into rubber, it can make the rubber have excellent wear-resisting, tear-resisting and flexibility.

2. As a kind of white dyestuff, because of the active zinc oxide has excellent activation performance, it has been utilized more and more widely in rubber products. For example, in the V type belt, it can not only take the place of common zinc oxide and it can reduce more than 1/2-1/3 of the using quantity which can make various performance and index of the rubber stable and make curing properties not be influenced so as to reduce the cost.

3. The fine grained zinc oxide can be used as medicine.

4. Due to the strong ability of absorbing the ultraviolet rays, more and more people use it to color the paint,printing ink and varnished cloth.

5. The zinc oxide also can be used to fields like press -sensitive, photocatalysis, photoelectrode, paint, and color developing areas, etc.

Zinc Oxide Rotary Kiln Technical Parameter

Specification

(m) | Kiln Size | Power

(kw) | Wight

(t) | Remarks |

| Diameter(m) | Length(m) | Slope(%) | Capacity

(t/d) | Speed

(r/min) |

| Φ2.5×40 | 2.5 | 40 | 3.5 | 180 | 0.44-2.44 | 55 | 149.61 |

|

| Φ2.5×50 | 2.5 | 50 | 3 | 200 | 0.62-1.86 | 55 | 187.37 |

|

| Φ2.5×54 | 2.5 | 54 | 3.5 | 280 | 0.48-1.45 | 55 | 196.29 | Kiln decomposition kilns |

| Φ2.7×42 | 2.7 | 42 | 3.5 | 320 | 0.10-1.52 | 55 | 198.5 | ------ |

| Φ2.8×44 | 2.8 | 44 | 3.5 | 450 | 0.437-2.18 | 55 | 201.58 | Kiln decomposition kilns |

| Φ3.0×45 | 3 | 45 | 3.5 | 500 | 0.5-2.47 | 75 | 201.94 | ------ |

| Φ3.0×48 | 3 | 48 | 3.5 | 700 | 0.6-3.48 | 100 | 237 | Kiln decomposition kilns |

| Φ3.0×60 | 3 | 60 | 4 | 800 | 0.3-2 | 100 | 310 | ------ |

| Φ3.2×50 | 3.5 | 50 | 4 | 1000 | 0.6-3 | 125 | 278 | Kiln decomposition kilns |

| Φ3.3×52 | 3.3 | 52 | 3.5 | 1300 | 0.266-2.66 | 125 | 283 | Preheating decomposition kilns |

| Φ3.5×54 | 3.5 | 54 | 3.5 | 1500 | 0.55-3.4 | 220 | 363 | Preheating decomposition kilns |

| Φ3.6×70 | 3.6 | 70 | 3.5 | 1800 | 0.25-1.25 | 125 | 419 | Waste heat power kilns |

| Φ4.0×56 | 4 | 56 | 4 | 2300 | 0.41-4.07 | 315 | 456 | Preheating decomposition kilns |

| Φ4.0×60 | 4 | 60 | 3.5 | 2500 | 0.396-3.96 | 315 | 510 | Preheating decomposition kilns |

| Φ4.2×60 | 4.2 | 60 | 4 | 2750 | 0.41-4.07 | 375 | 633 | Preheating decomposition kilns |

| Φ4.3×60 | 4.3 | 60 | 3.5 | 3200 | 0.396-3.96 | 375 | 583 | Preheating decomposition kilns |

| Φ4.5×66 | 4.5 | 66 | 3.5 | 4000 | 0.41-4.1 | 560 | 710.4 | Preheating decomposition kilns |

| Φ4.7×74 | 4.7 | 74 | 4 | 4500 | 0.35-4 | 630 | 849 | Preheating decomposition kilns |

| Φ4.8×74 | 4.8 | 74 | 4 | 5000 | 0.396-3.96 | 630 | 899 | Preheating decomposition kilns |

| Φ5.0×74 | 5 | 74 | 4 | 6000 | 0.35-4 | 710 | 944 | Preheating decomposition kilns |

| Φ5.6×87 | 5.6 | 87 | 4 | 8000 | Max4.23 | 800 | 1265 | Preheating decomposition kilns |

| Φ6.0×95 | 6 | 95 | 4 | 10000 | Max5 | 950×2 | 1659 | Preheating decomposition kilns |