Carbide slag dryer Product Description

Calcium carbide slag is the waste slag after calcium carbide is hydrolyzed to obtain acetylene gas. Its main components are calcium hydroxide and water. Calcium carbide slag pollutes the environment and water resources greatly. After a series of production and processing, such as crushing, grinding and drying of calcium carbide slag, it can be reused to reduce its harm to the environment and water source.

The carbide slag dryer is developed by using a unique production process. It has the characteristics of reasonable structure, simple operation, low energy consumption, large processing capacity, etc. It is popular with users in the market and can make users gain more considerable profits.

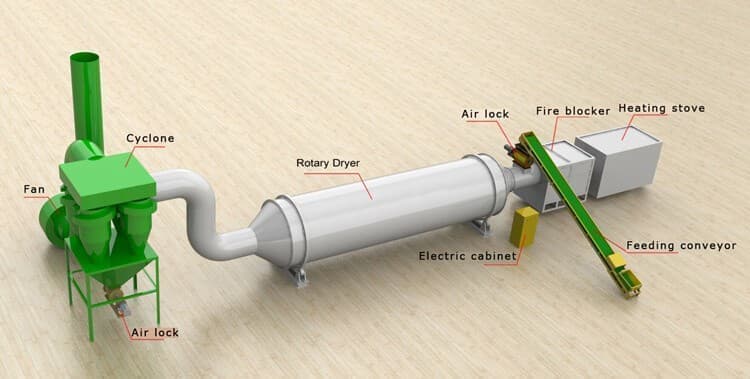

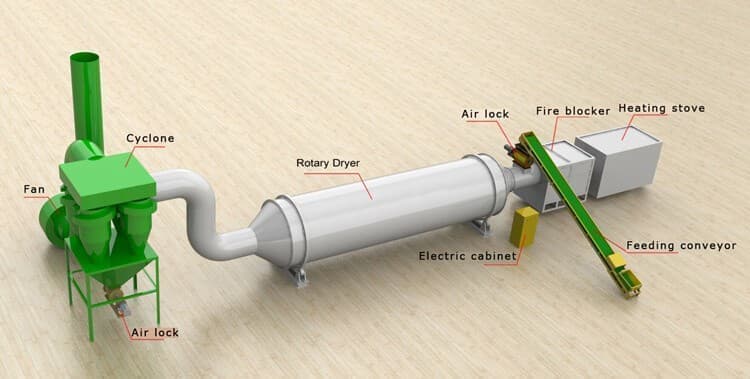

The carbide slag dryer has a reasonable and compact structure, which is easy to install and operate. The equipment is mainly composed of cylinder, induced draft device, dust removal device, electric control device, feeding device, discharging device, exhaust device, feed plate, transmission device and other components.

Carbide slag dryer Working Principle

The calcium carbide slag materials with large moisture content are sent to the hopper by the belt conveyor, and then enter the feeding end. The slope of the feeding pipe is slightly greater than the natural inclination of the materials, which is mainly to facilitate the materials to flow into the dryer. The cylinder of the dryer is inclined to the horizontal line to a certain extent. The material is added from the higher end.

The heat carrier and the material enter the cylinder in the same direction or in the opposite direction. When the cylinder rotates, the material inside it moves to the lower end under the action of gravity. In this way, the wet material can directly or indirectly get the heat of the heat carrier, so as to achieve the drying of the material. The dried material is sent out by the screw conveyor.

Carbide slag dryer Features And Advantages

1. The volume of the cylinder is expanded, the material handling capacity is increased, and the output of the equipment is increased.

2. The cylinder is well sealed, and there is no dust overflow during operation, creating a good working environment for operators.

3. The heat insulation of the equipment barrel is strong, which can reduce the heat loss in production and save more than 10% - 15% of the fuel cost for users every year.

4. The equipment has a relatively simple structure, which is convenient for users to install, operate and maintain.

5. The built-in material shifting plate can dry the materials in the cylinder evenly and efficiently.

Carbide slag dryer Technical Parameter

specs(m)

(diameter × length) | Cylinder volume

(m³) | throughput

(t/h) | Slope

(%) | air temperature

(℃) | Main motor

(kw) | Total weight

(t) |

| Φ1.2×8.0 | 9.0 | 1.9-2.4 | 3-5 | 700-800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4-3.0 | 3-5 | 700-800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5-5.7 | 3-5 | 700-800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3-6.6 | 3-5 | 700-800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7-7.1 | 3-5 | 700-800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5-8.1 | 3-5 | 700-800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6-9.5 | 3-5 | 700-800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7-12.2 | 3-5 | 700-800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4-14.2 | 3-5 | 700-800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0-16.2 | 3-5 | 700-800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5-16.9 | 3-5 | 700-800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4-21.7 | 3-5 | 700-800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3-24.1 | 3-5 | 700-800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2-26.5 | 3-5 | 700-800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2-34.0 | 3-5 | 700-800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1-37.7 | 3-5 | 700-800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7-47.1 | 3-5 | 700-800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9-53.6 | 3-5 | 700-800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8-76.0 | 3-5 | 700-800 | 160 | 135 |