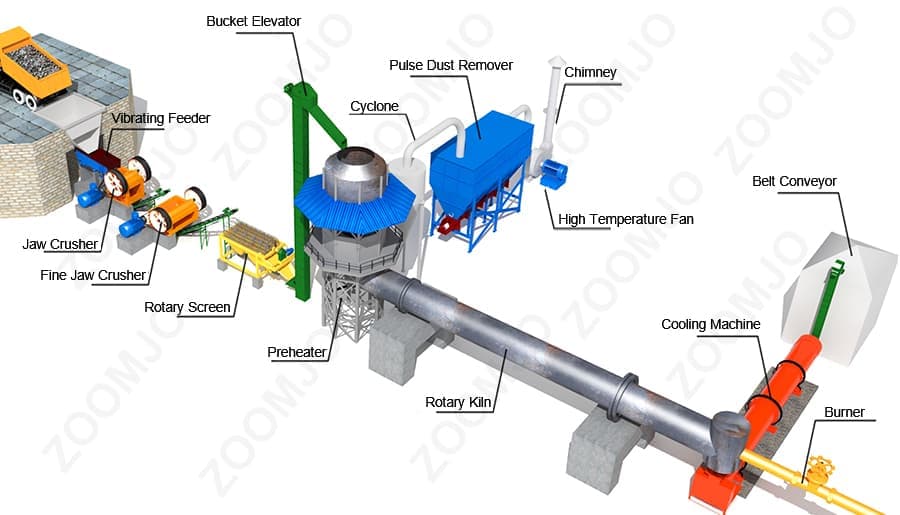

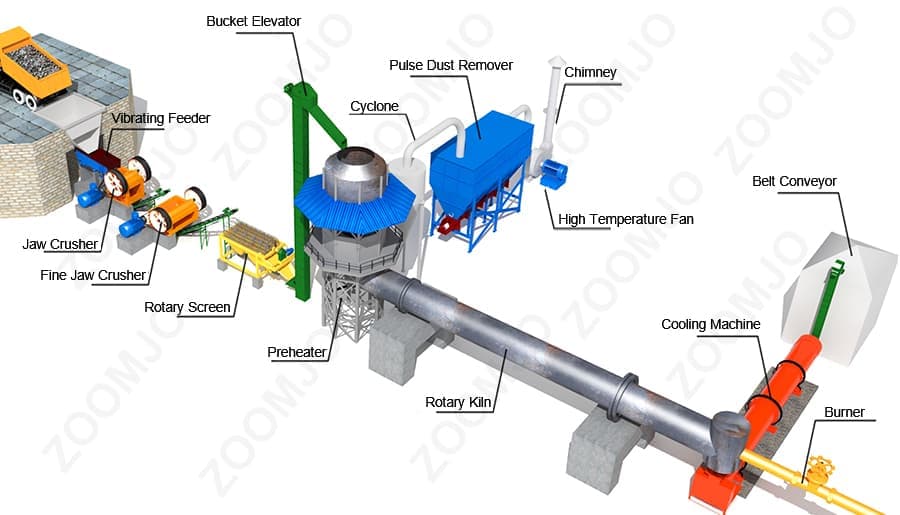

Active Lime Rotary Kiln Product Description

Active lime rotary kiln is composed of cylinder, gears,support device, kiln liner and kiln tail sealing equipment, hood of kiln head and alkene material device etc..Active Lime rotary kiln as a heating device is a high-quality steel processed, is supported on the support device by tyer, and there is hydraulic pressure catch wheel on the first or some gear in order to control the turning of cylinder.Gearing gyrate according to process-required rotating speed by ring gear in the middle of cylinder.

Because of the need of installation or maintenance, the bigger Active lime rotary kiln has auxiliary gears, which makes cylinder gyrate more slowly. To prevent cold air come in and dust overflow, the reliable kiln tail and hed sealing equipment are installed on feed and discharge end.The most common are Cement clinker Rotary kiln, etc., more models to choose.

Active Lime Rotary Kiln Working Principle

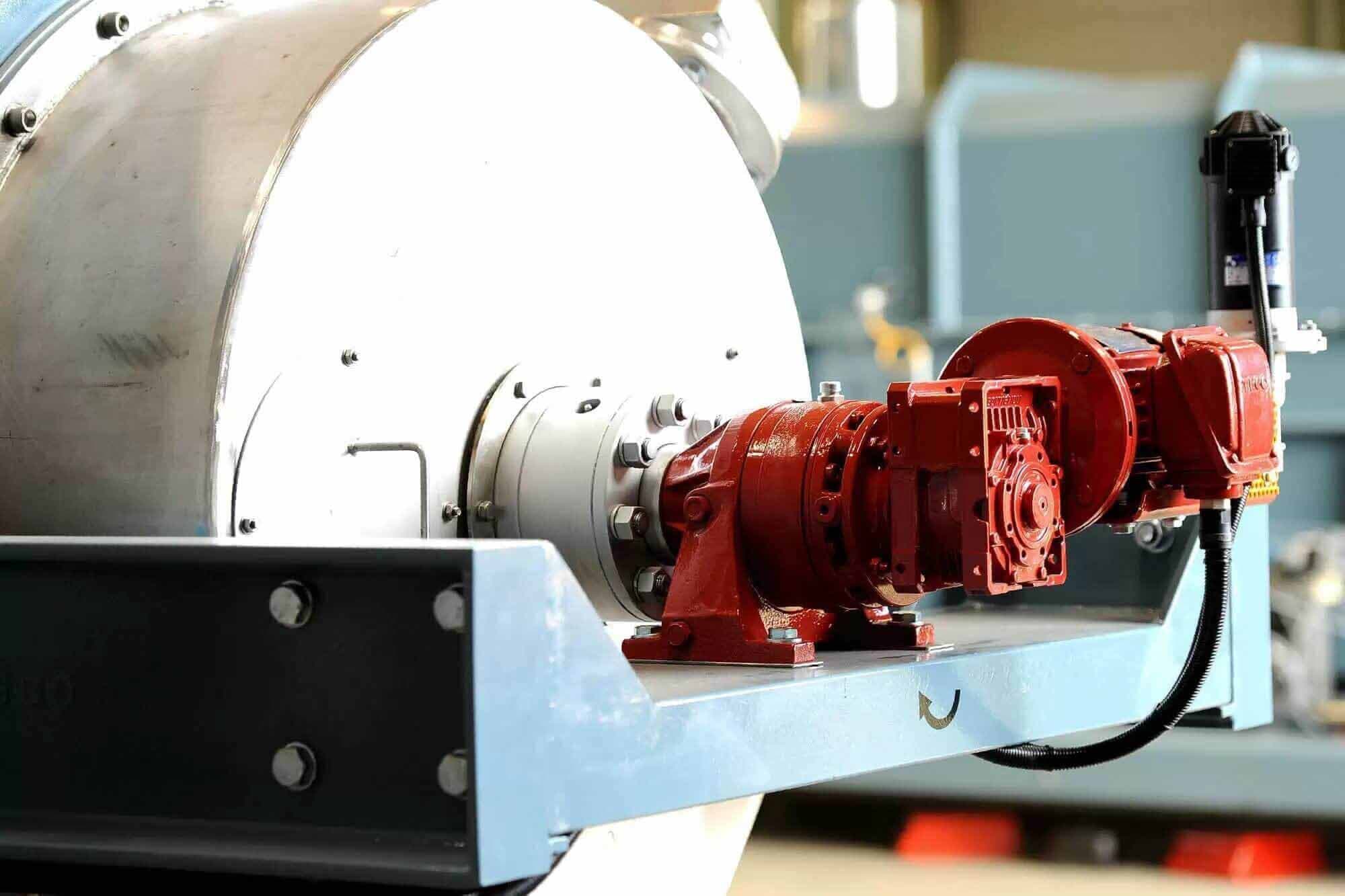

The barrel of the lime rotary kiln is made of rolled steel plates, with a refractory lining inside the barrel and a specified slope from the horizontal line, supported by three wheel belts on each blocking support device, and a large gear ring fixed with a tangential spring plate on the barrel across the barrel near the feeding end, with a small gear meshing with it underneath.

In normal operation, the rotary kiln is powered by the main drive motor via the main reducer to this open gear unit, which drives the rotary kiln and the material enters the kiln from the end of the kiln (the top end of the barrel).

Due to the tilting and slow rotation of the cylinder, the material both rolls in a circular direction and moves axially (from the high end to the low end) to continue its process, finally producing clinker that enters the cooler through the kiln head hood. The fuel is sprayed into the kiln from the kiln head and the exhaust gas from the combustion is exchanged with the material for the impact crusher and then exported from the end of the kiln.

Active Lime Rotary Kiln Features And Advantages

1.Cylinder tyer bolster: lower bolster has three types: fixed, zoom and floating. The structure has simple replacement that is convenient and won't hurt cylinder.

2.Gears:single or double. Control the rotating speed by blucher, DE machine and frequency variable motor. Reliable energy-saving, and efficient.

3.Sealing equipment:there are many kinds for choice according to kiln models .

4.Spring edge sealing, graphite block sealing and combination for above. The feather is adaptive for cylinder rotating and swing. And sealing effect is very good.

5.Support device:advanced shaft structure, automatic temperature measuring device and electrical heating.

Active Lime Rotary Kiln Technical Parameter

| Design capacity(t/d) | 150 | 200 | 250 | 300 | 350 | 400 | 500 | 600 | 750 |

| Product | Active lime dolomite | Active lime dolomite | Active lime dolomite | Active lime dolomite | Active lime dolomite | Active lime dolomite | Active lime | Active lime | Active lime |

Preheater | Square six pusher vertical preheater | Square six pusher vertical preheater | Square six pusher vertical preheater | Polygon eight pusher vertical preheater | Polygon eight pusher vertical preheater | Polygon eight pusher vertical preheater | Polygon eight pusher vertical preheater | Polygon twelve pusher vertical preheater | Polygon twelve pusher vertical preheater |

| Rotary kiln | Specific

ation(m) | Φ2.5×40 | Φ2.8×43 | Φ3×48 | Φ3.2×50 | Φ3.5×54 | Φ3.6×56 | Φ3.8×58 | Φ4×60 | Φ4.3×60 |

| Interface Size(㎡) | 280 | 320 | 390 | 430 | 490 | 540 | 600 | 660 | 725 |

Burning Tempe

rature | 1300/1250 | 1300/1250 | 1300/1250 | 1300/1250 | 1350 | 1350 | 1350 | 1350 | 1350 |

| Rotary Slope | 3.5% | 3.5% | 3.5% | 3.5% | 3% | 3% | 3% | 3% | 3% |

Suppor

ting Number | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| Gear Wheel Type | machinery | machinery | machinery | hydraulic | hydraulic | hydraulic | hydraulic | hydraulic | hydraulic |

Cooling

Machine | Square vertical cooler | Square vertical cooler | Square vertical cooler | Square vertical cooler | Square vertical cooler | Square vertical cooler | Square vertical cooler | Square vertical cooler | Square vertical cooler |

| Fuel | Coal gas Pulverized coal | Coal gas Pulverized coal | Coal gas Pulverized coal | Coal gas Pulverized coal | Coal gas Pulverized coal | Coal gas Pulverized coal | Coal gas Pulverized coal | Coal gas Pulverized coal | Coal gas Pulverized coal |

Heat Consum

ption (KJ/KgCaO) | 5300/5000 | 5300/5000 | 5300/5000 | 5300/5000 | 5200 | 5200 | 5100 | 5100 | 4810 |