Coal dryer Product Description

It is a kind of coal with low degree of coalification. It is not only of great use value in agriculture, but also of great use in chemical industry, medicine, architecture, ceramics and other fields.

The peat dryer has a good effect on peat dehydration and drying. It is a widely used drying equipment. It is not only affordable, convenient to operate, energy saving and environmental protection, but also has a large processing capacity, which can create higher profits for users. The following specific analysis of the structure, advantages, working principle, etc. of the peat dryer.

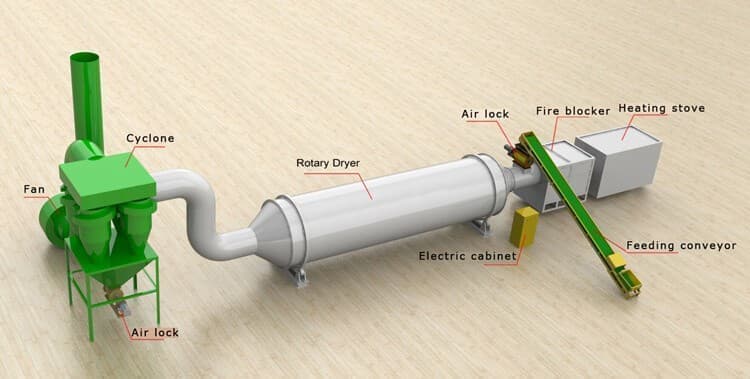

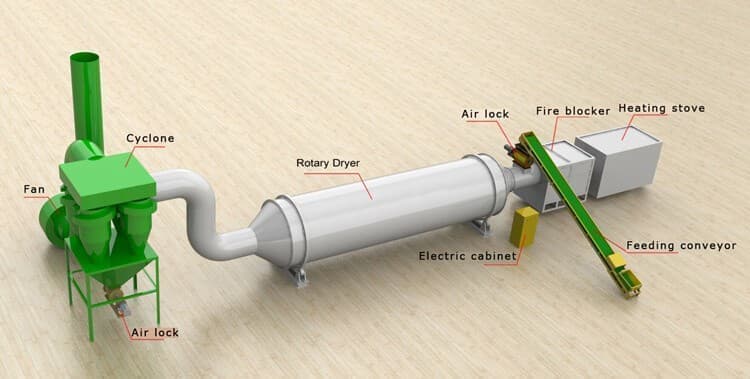

The peat dryer is mainly composed of cylinder, feeding plate, transmission device, electric control device, induced draft device, dust removal device, feeding device, discharging device, cleaning device, exhaust pipe and other components.

Coal dryer Working Principle

When the peat dryer is operating, the wet materials are first sent to the hopper by the belt conveyor, and then the feeder of the hopper enters the feeding end through the feeding pipe. The slope of the feeding pipe should be greater than the natural inclination of the material, which can make the material enter the dryer smoothly. The dryer is a cylinder with a certain angle with the horizontal line.

The material enters the cylinder from the higher end, and the heat carrier enters the cylinder from the same direction or the opposite direction with the material. With the rotation of the cylinder, the material moves from the higher end to the lower end under the action of gravity, In the process of moving, the materials directly or indirectly get the heat of the heat carrier, so that the wet materials can be dried and the peat can be dehydrated and dried.

Coal dryer Features And Advantages

1. The cylinder has a good sealing property, which not only reduces the heat loss in production, but also effectively reduces the dust overflow in production, making the production of equipment more environmentally friendly and energy-saving.

2. The volume of the cylinder is expanded to increase the drying capacity of the cylinder for peat per unit time, which improves the drying efficiency of the equipment.

3. The design is simple, the structure is compact, and the floor area is small, which reduces the user's expenditure on infrastructure and makes the user's production operation more convenient.

4. The equipment has strong stability and low noise during operation, which makes the equipment safer and more reliable in production and can bring higher profits for users.

Coal dryer Technical Parameter

Model(m)

| Volume

(m³) | throughput

(t/h) | slope

(%) | air temperature

(℃) | motor

(kw) | weight

(t) |

| Φ1.2×8.0 | 9.0 | 1.9-2.4 | 3-5 | 700-800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4-3.0 | 3-5 | 700-800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5-5.7 | 3-5 | 700-800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3-6.6 | 3-5 | 700-800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7-7.1 | 3-5 | 700-800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5-8.1 | 3-5 | 700-800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6-9.5 | 3-5 | 700-800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7-12.2 | 3-5 | 700-800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4-14.2 | 3-5 | 700-800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0-16.2 | 3-5 | 700-800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5-16.9 | 3-5 | 700-800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4-21.7 | 3-5 | 700-800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3-24.1 | 3-5 | 700-800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2-26.5 | 3-5 | 700-800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2-34.0 | 3-5 | 700-800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1-37.7 | 3-5 | 700-800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7-47.1 | 3-5 | 700-800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9-53.6 | 3-5 | 700-800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8-76.0 | 3-5 | 700-800 | 160 | 135 |