Wood chip dryers are an important part of biomass fuel production equipment. By drying wood chips, they can be further pelletized to produce combustible biomass fuels. Sawdust dryers play an important role in the recycling of biomass fuels and are of great significance in promoting economic development and environmental protection.

The wood chip dryer is a special equipment designed and manufactured for drying wood chips, sawdust, wood flour, wood chips and other materials. We produce three-way rotary drum dryers, which are usually used for drying wood chips, wood shavings and shavings, wood flour, etc.. It can dry wet materials with a moisture content of 60% to a dry product with a moisture content of less than 12%. Compared to conventional dryers, the 3-stage wood chip rotary dryer has a 50% reduction in floor space and improved drying efficiency. The wood chip rotary dryer can be used for drying moisture or granular materials in the mineral processing, construction materials, metallurgical and chemical industries. Wood chip rotary dryers are used for drying a wide range of materials and are simple and reliable to operate, making them widely available.

Wood chip rotary dryers from the ZOOMJO Group are characterised by high drying output, significant energy savings and low maintenance costs. Our wood chip dryer plants include a heating section, feeder, rotary dryer, discharger and cyclone dust collector. We can also supply complete drying and pelletizing equipment in order to provide a one-stop solution for our customers.

Wood Chip Dryer

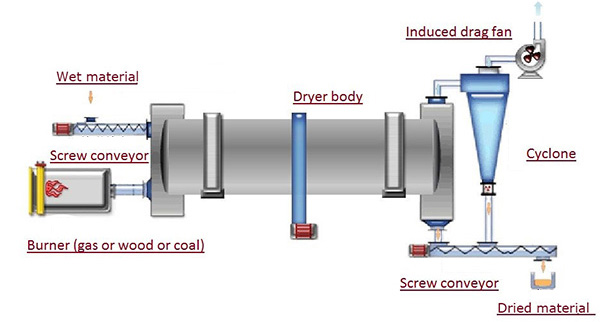

The wood chip rotary dryer consists of a heating device, feeding device, conveying device, rotary drum dryer, discharging device, dust removal device and other connected parts.

The wet material first enters the inner layer with the hot air, then enters the second and outer layers until it is discharged with the hot air.

At the same time, heat exchange takes place between the hot air and the raw material. The inner corner plates are designed to disperse the wet wood or power for more heat exchange.

1. 50% shorter machine length compared to a single drum dryer, reducing floor space and saving approximately 40% of the project investment.

2. Multiple heating sources. Customers can choose the heating source according to their situation and we can design customised solutions for them.

3. Internal structure designed for sawdust materials. Drying efficiency up to 90-95%.

4. The system is equipped with a PLC system and video monitoring system for high automation and easy operation.

5. This system has a unique sealing structure with no heat leakage.

6. low investment, low running cost and short payback time

7. Use the best quality components to ensure safe and reliable operation.

| Specificationsm) | volume (m³) | throughput (t/h) | Installation slope (%) | air temperature (℃) | Main motor (kw) | weight (t) |

| Φ1.2×8.0 | 9.0 | 1.9-2.4 | 3-5 | 700-800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4-3.0 | 3-5 | 700-800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5-5.7 | 3-5 | 700-800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3-6.6 | 3-5 | 700-800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7-7.1 | 3-5 | 700-800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5-8.1 | 3-5 | 700-800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6-9.5 | 3-5 | 700-800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7-12.2 | 3-5 | 700-800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4-14.2 | 3-5 | 700-800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0-16.2 | 3-5 | 700-800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5-16.9 | 3-5 | 700-800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4-21.7 | 3-5 | 700-800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3-24.1 | 3-5 | 700-800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2-26.5 | 3-5 | 700-800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2-34.0 | 3-5 | 700-800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1-37.7 | 3-5 | 700-800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7-47.1 | 3-5 | 700-800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9-53.6 | 3-5 | 700-800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8-76.0 | 3-5 | 700-800 | 160 | 135 |