Lignite dryer Product Description

In nature, lignite raw ore contains a lot of water, which must be dried and dehydrated before it can be applied to the industrial field. For this reason, zoomjo group has specially developed a special drying equipment for lignite, namely lignite dryer, which has significant characteristics in terms of quality and performance.

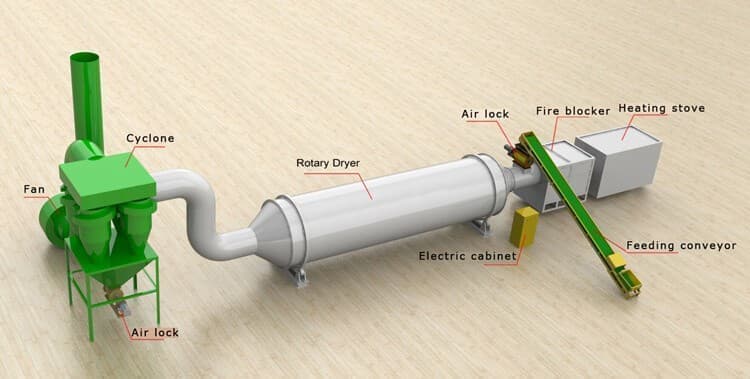

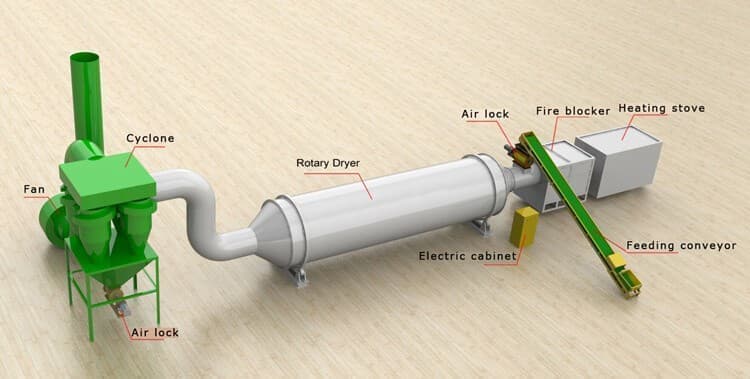

The main structure of the lignite dryer includes the cylinder, lifting plate, pinion, motor, idler, stop roll, reducer, gear, front roll ring, rear roll ring, discharge section, feed chute, hot air duct, furnace body, etc. The overall structure design is simple and compact, with novel, unique, reasonable and other characteristics. The weight is reduced by two thirds of the traditional dryer, the degree of automation is more than doubled, and the operation is easy, The cost is also greatly reduced.

Lignite dryer Working Principle

The lignite dryer is composed of a cylindrical structure. The cylinder is placed horizontally, one end is slightly higher and the other end is slightly lower.

When the equipment is working, the wet lignite is sent to the feeding hopper through a belt conveyor or bucket elevator, and then the lignite enters the dryer from the higher end of the dryer. The dryer keeps rotating, and the lignite in the cylinder is brought to a higher place with the rotation and then falls.

Lignite dryer Features And Advantages

1. It is processed and manufactured by the advanced production process in Germany. The abrasion resistance and corrosion resistance of raw materials are good in the market, with strong pertinence to lignite and stable operation.

2. Gear, lifting plate, cylinder and other devices are reasonably designed, with accurate parameters, higher safety and almost zero failure rate.

3. The water content in the finished product has been greatly reduced, and the grade has been increased by more than 45%, which is in line with the production requirements of the processing plant and the material requirements of the corresponding fields.

4. The thermal insulation layer is set to reduce the heat energy consumption, the power consumption is also extremely low, and the cost is reduced by ¥30000 to ¥60000 .

Lignite dryer Technical Parameter

Model(m)

| Volume

(m³) | throughput

(t/h) | slope

(%) | air temperature

(℃) | motor

(kw) | weight

(t) |

| Φ1.2×8.0 | 9.0 | 1.9-2.4 | 3-5 | 700-800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4-3.0 | 3-5 | 700-800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5-5.7 | 3-5 | 700-800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3-6.6 | 3-5 | 700-800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7-7.1 | 3-5 | 700-800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5-8.1 | 3-5 | 700-800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6-9.5 | 3-5 | 700-800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7-12.2 | 3-5 | 700-800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4-14.2 | 3-5 | 700-800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0-16.2 | 3-5 | 700-800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5-16.9 | 3-5 | 700-800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4-21.7 | 3-5 | 700-800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3-24.1 | 3-5 | 700-800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2-26.5 | 3-5 | 700-800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2-34.0 | 3-5 | 700-800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1-37.7 | 3-5 | 700-800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7-47.1 | 3-5 | 700-800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9-53.6 | 3-5 | 700-800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8-76.0 | 3-5 | 700-800 | 160 | 135 |