Biomass dryer Product Description

The biomass dryer manufactured by our company adopts a triple pass rotary drum dryer, which greatly improves the drying capacity through the way of downstream heating. The wood chip dryer has the characteristics of simple structure, large processing capacity, high thermal efficiency, easy maintenance, low cost and so on. It is widely used in the drying of wood chips, sawdust, bamboo chips, wood chippings, shavings, barley straw, oat straw, wheat straw, rye straw, rice straw, sorghum straw, straw and corn straw as well as potato vines, bean stalks, etc.

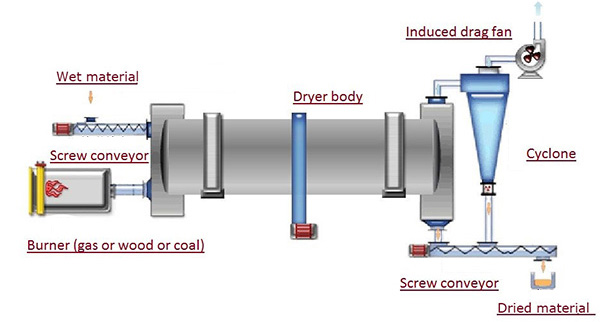

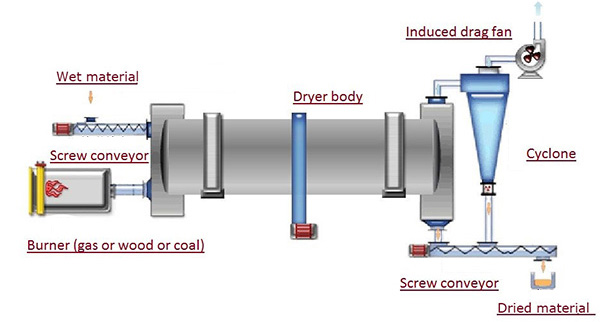

Biomass dryer Working Principle

The material firstly enters the inner layer of the rotary drum by the feeding device to achieve downstream drying, which is constantly copied up and scattered under the copying board of the inner layer to achieve heat exchange in a spiral marching type; then moves to the other end of the inner layer to enter the middle layer for counter-current drying, which is repeatedly raised into the middle layer, in a marching way of two steps in and one step out; then in the middle layer it can fully absorb the heat emitted from the inner layer of the drum, and also absorb the heat from the middle layer of the drum.

Then in the middle layer can fully absorb both the heat emitted by the inner layer drum and the heat of the middle layer drum, and at the same time prolong the drying time, the material reaches the best drying state here.

Finally, the material travels to the other end of the middle layer and falls into the outer layer, and travels in a rectangular multi-loop manner in the outer roller. The material that achieves the drying effect quickly travels under the action of the hot air and is discharged from the roller, while the wet material that does not achieve the drying effect cannot travel quickly due to its own weight, and is fully dried in this rectangular copying plate, thus completing the entire drying process.

Biomass dryer Features And Advantages

1. Low energy consumption

The dryer of our factory selects reasonable operating parameters, and the coal consumption and power consumption are reduced by more than 10-15% compared with ordinary dryers.

2. High thermal efficiency

The downstream drying method is adopted. The material and heat source air flow enter the drying equipment from the same side. The outlet temperature of the dryer is low and the thermal efficiency is high.

3. Large processing capacity and small floor area

The air dryer has simple structure, small floor area and is easy to build and maintain. Large processing capacity and high thermal efficiency.

4. Simple structure and convenient operation

The utility model has the advantages of excellent structure, simple structure, stable operation of materials through the resistance of the cylinder, and convenient operation.

Biomass dryer Technical Parameter

Specificationsm)

| volume

(m³) | throughput

(t/h) | Installation slope

(%) | air temperature

(℃) | Main motor

(kw) | weight

(t) |

| Φ1.2×8.0 | 9.0 | 1.9-2.4 | 3-5 | 700-800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4-3.0 | 3-5 | 700-800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5-5.7 | 3-5 | 700-800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3-6.6 | 3-5 | 700-800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7-7.1 | 3-5 | 700-800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5-8.1 | 3-5 | 700-800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6-9.5 | 3-5 | 700-800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7-12.2 | 3-5 | 700-800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4-14.2 | 3-5 | 700-800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0-16.2 | 3-5 | 700-800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5-16.9 | 3-5 | 700-800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4-21.7 | 3-5 | 700-800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3-24.1 | 3-5 | 700-800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2-26.5 | 3-5 | 700-800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2-34.0 | 3-5 | 700-800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1-37.7 | 3-5 | 700-800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7-47.1 | 3-5 | 700-800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9-53.6 | 3-5 | 700-800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8-76.0 | 3-5 | 700-800 | 160 | 135 |