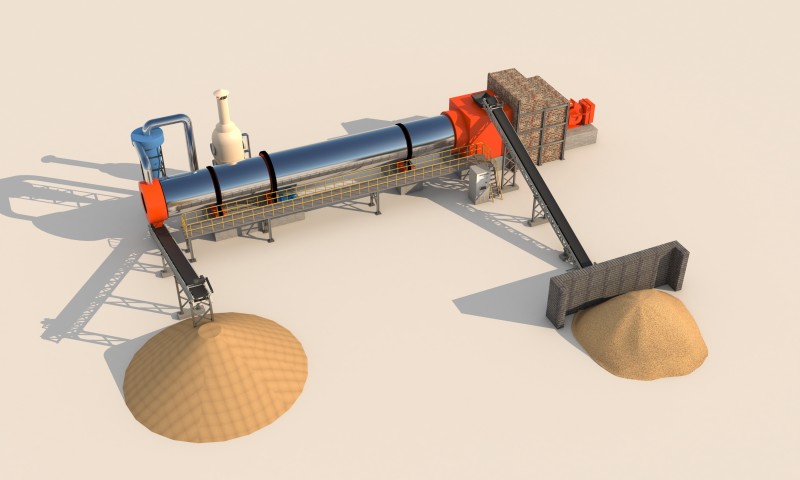

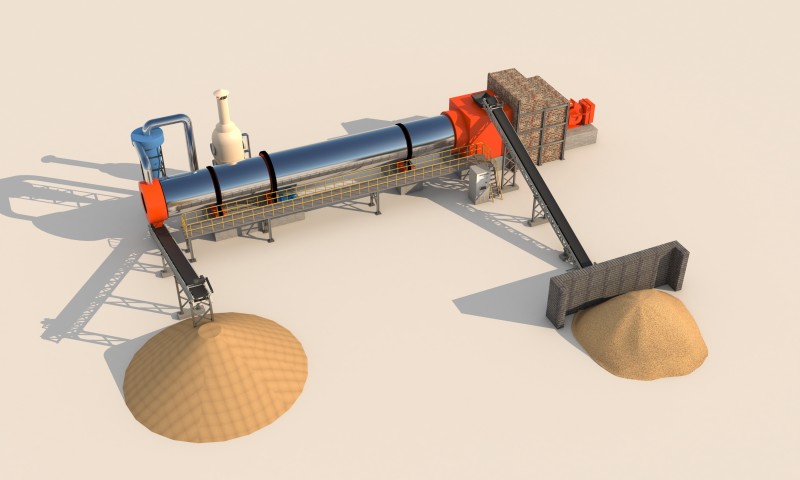

Rotary Drum Dryer Product Description

The rotary drum dryer manufactured by our company, also called dryer. It is widely used in building material, metallurgy, chemical engineering, and cement industries for the drying of slag lime stone, powdered coal, slag and clay.The drying machine has the features of reasonable structure, fine processing, high output, low energy consumption, and convenient running. This rotary drum dryer consists of rotary body, throwing filtch, transmission device, supporting device and sealing ring.

Rotary Drum Dryer Working Principle

Wet material from the belt conveyor or bucket elevator to the hopper, and then by feeder feeding through the feeding device into the terminal. Rotary dryer cylinder into a slightly tilted to the horizontal rotating cylinder. Adding material from the higher end, low-end entry by the heat carrier, and the material into a counter-current contact, but also heat carrier and the material together and flow into the cylinder.

With the rotating cylinder, the material runs by gravity to a more bottom end. Wet material in the cylinder body to move forward the process, directly or indirectly heating the heat carrier, the wet material to dry, and then the discharge end by the belt conveyor or screw conveyor sent.

Rotary Drum Dryer Features And Advantages

1.The new inner structure strengthens the cleaning and heat conduction of the dispersed material, and eliminates the bonding in the inner drum wall. The adaptability to the material moisture and stickiness is stronger.

2.It adopts direct flow drying method. The gas fume and the material go to the dryer from the same side. By using the hyperthermia gas fume, the evaporation strength is very high. With the low outlet temperature, the heat efficiency is very high.

3.The operating parameter can be changed according to different materials. So that the material can form a stable fabric curtain and achieve fully heat exchange.

4.The granularity and the moisture and be controlled by the customer's demand. When drying the coal slurry, the product moisture can be less than 8% and the granularity and be less than 8mm.

5.The dryer is of strong overload capacity resistance, large process load, low fuel consumption, and low cost.

6.The zero level thrust of the dryer reduces the abrasion to the catch wheel and the riding wheel. The operation of the rotary drum is stable and reliable.

7.The dryer adopts the riding wheel device, which make the riding wheel and the rolling ring linear touch all the time. Thus the abrasive and the power loss are greatly reduced.

8.The new type feeding and discharging device solve the problem of feeding jam, discontinuous and uneven feeding, and returning charge which lighten the load of dedusting system.

Rotary Drum Dryer Technical Parameter

| Model (m) | Gradient (degree) | Revolving speed (r/min) | Volume (m3) | Power (kw) | Capacity (t/h) | Weight (t) |

| SSJX 0.6*8 | 3-5 | 8 | 2.26 | 4 |

| 2.9 |

| SSJX 0.8*10 | 3-5 | 7.2 | 5.02 | 4 |

| 4.5 |

| SSJX 1.0*10 | 3-5 | 6.73 | 7.85 | 5.5 | 5-8 | 5.6 |

| SSJX 1.2*12 | 3-5 | 5.8 | 13.31 | 11 | 8-12 | 14.8 |

| SSJX 1.5*12 | 3-5 | 4.8 | 21.2 | 15 | 10-15 | 17.8 |

| SSJX 1.8*14 | 3-5 | 3.2 | 48.22 | 30 | 12-18 | 27 |

| SSJX 2.2*18 | 3-5 | 3 | 70.43 | 37 | 15-20 | 53.8 |

| SSJX 2.4*20 | 3-5 | 2.83 | 90.43 | 45 | 20-25 | 60 |

| SSJX 2.8*24 | 3-5 | 2.59 | 147.8 | 75 | 25-30 | 67 |

| SSJX 3*20 | 3-5 | 1.5-5 | 141.3 | 55 | 25-35 | 78 |

| SSJX 3*25 | 3-5 | 1.5-5 | 176.6 | 75 | 32-40 | 104 |