DRI sponge iron Rotary Kiln Product Description

Sponge iron ore is one of the primary iron ores, which contains iron oxide with water as the main component and is a red natural multi-mineral deposit mixture. It has a low iron content, with a particle size of less than 10mm and a moisture content of less than 15% of hematite powder mixed with a portion of 0.8 coal powder into the reversing kiln.

The hematite ore completes the drying, magnetisation and desulphurisation process in the same reversing kiln with a reversing kiln speed of 0.8 rpm; the flame temperature and flame shape of the sponge iron rotary kiln should be adjusted frequently to meet the actual production needs.

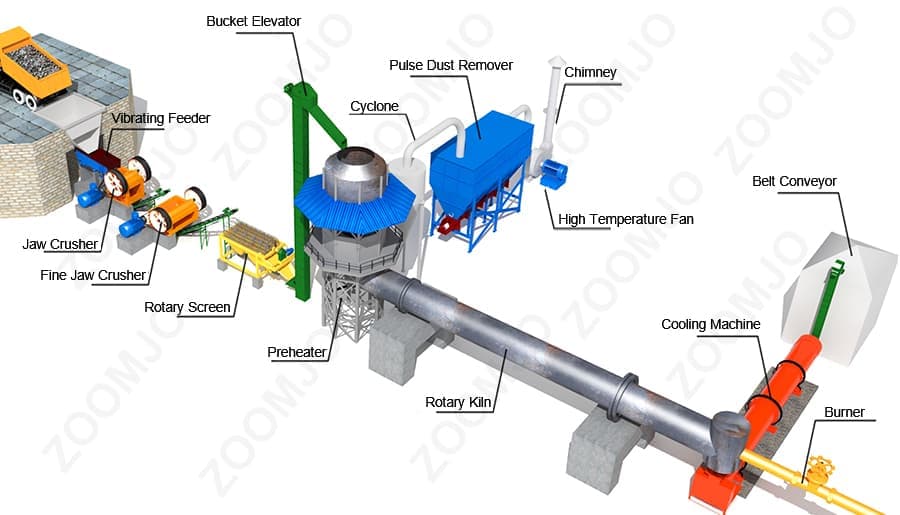

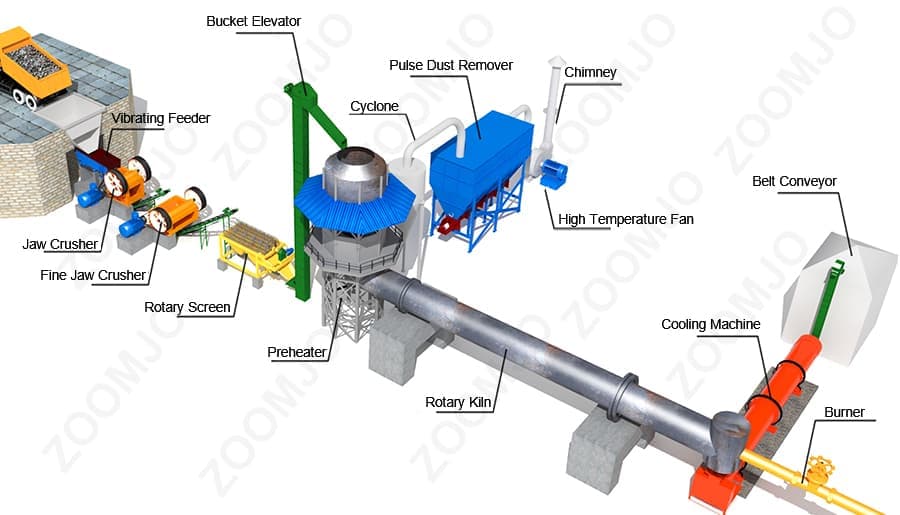

DRI sponge iron Rotary Kiln Working Principle

1. The raw material (dolomite) is crushed by a crusher to a qualified material (30-40mm).

2. Sintered by rotary kiln and calcined to calcined white.

3. Cooled by a cooler.

4. Then passed through the ball mill to grind into powder.

5. Then pressed into balls by a ball press.

6. Crushed and mixed with ferrosilicon powder (containing 75% silicon) and fluorspar powder (containing GaF2)=95%) to make a homogeneous mass.

7. Loaded into a heat-resistant stainless steel reduction tank, placed in a reduction furnace, at 1200-1250°C and vacuum of 1.33 Pa vacuum degree reduction to produce crude.

8. After melt refining, ingot casting, surface treatment to obtain finished magnesium ingots.

DRI sponge iron Rotary Kiln Features And Advantages

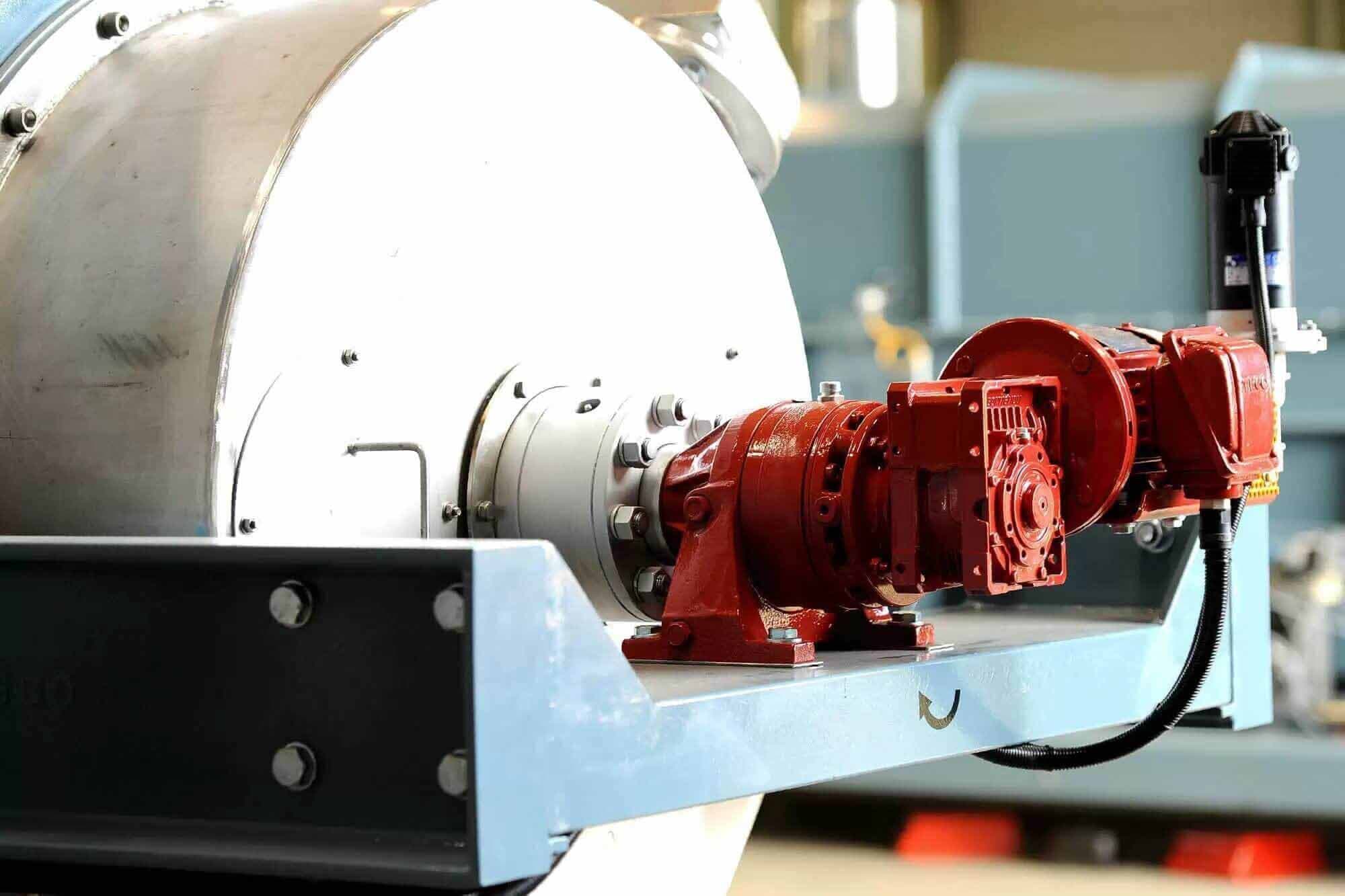

1. Support equipment: spindle layout, set with active temperature measuring equipment and electric heating equipment, together with movable supports for selection.

2. Shift wheel equipment: divided into two types: mechanical wheel and hydraulic thrust shift wheel. Hydraulic retaining wheel equipment is equipped with hydraulic control system.

3. Transmission equipment: with single transmission or double transmission. DC motor or frequency-controlled motor control speed, work reliably.

Rotary kiln calcination of sponge iron fuel used

According to its state, can be divided into:

1. solid fuel, such as coal, coke, etc.;

2. liquid fuel, such as heavy oil, paraffin, diesel fuel, etc.;

3. gas fuel, such as liquefied petroleum gas, furnace gas, natural gas, etc.

DRI sponge iron Rotary Kiln Technical Parameter

Specification

(m) | Kiln Size | Power

(kw) | Wight

(t) | Remarks |

| Diameter(m) | Length(m) | Slope(%) | Capacity

(t/d) | Speed

(r/min) |

| Φ2.5×40 | 2.5 | 40 | 3.5 | 180 | 0.44-2.44 | 55 | 149.61 |

|

| Φ2.5×50 | 2.5 | 50 | 3 | 200 | 0.62-1.86 | 55 | 187.37 |

|

| Φ2.5×54 | 2.5 | 54 | 3.5 | 280 | 0.48-1.45 | 55 | 196.29 | Kiln decomposition kilns |

| Φ2.7×42 | 2.7 | 42 | 3.5 | 320 | 0.10-1.52 | 55 | 198.5 | ------ |

| Φ2.8×44 | 2.8 | 44 | 3.5 | 450 | 0.437-2.18 | 55 | 201.58 | Kiln decomposition kilns |

| Φ3.0×45 | 3 | 45 | 3.5 | 500 | 0.5-2.47 | 75 | 201.94 | ------ |

| Φ3.0×48 | 3 | 48 | 3.5 | 700 | 0.6-3.48 | 100 | 237 | Kiln decomposition kilns |

| Φ3.0×60 | 3 | 60 | 4 | 800 | 0.3-2 | 100 | 310 | ------ |

| Φ3.2×50 | 3.5 | 50 | 4 | 1000 | 0.6-3 | 125 | 278 | Kiln decomposition kilns |

| Φ3.3×52 | 3.3 | 52 | 3.5 | 1300 | 0.266-2.66 | 125 | 283 | Preheating decomposition kilns |

| Φ3.5×54 | 3.5 | 54 | 3.5 | 1500 | 0.55-3.4 | 220 | 363 | Preheating decomposition kilns |

| Φ3.6×70 | 3.6 | 70 | 3.5 | 1800 | 0.25-1.25 | 125 | 419 | Waste heat power kilns |

| Φ4.0×56 | 4 | 56 | 4 | 2300 | 0.41-4.07 | 315 | 456 | Preheating decomposition kilns |

| Φ4.0×60 | 4 | 60 | 3.5 | 2500 | 0.396-3.96 | 315 | 510 | Preheating decomposition kilns |

| Φ4.2×60 | 4.2 | 60 | 4 | 2750 | 0.41-4.07 | 375 | 633 | Preheating decomposition kilns |

| Φ4.3×60 | 4.3 | 60 | 3.5 | 3200 | 0.396-3.96 | 375 | 583 | Preheating decomposition kilns |

| Φ4.5×66 | 4.5 | 66 | 3.5 | 4000 | 0.41-4.1 | 560 | 710.4 | Preheating decomposition kilns |

| Φ4.7×74 | 4.7 | 74 | 4 | 4500 | 0.35-4 | 630 | 849 | Preheating decomposition kilns |

| Φ4.8×74 | 4.8 | 74 | 4 | 5000 | 0.396-3.96 | 630 | 899 | Preheating decomposition kilns |

| Φ5.0×74 | 5 | 74 | 4 | 6000 | 0.35-4 | 710 | 944 | Preheating decomposition kilns |

| Φ5.6×87 | 5.6 | 87 | 4 | 8000 | Max4.23 | 800 | 1265 | Preheating decomposition kilns |

| Φ6.0×95 | 6 | 95 | 4 | 10000 | Max5 | 950×2 | 1659 | Preheating decomposition kilns |