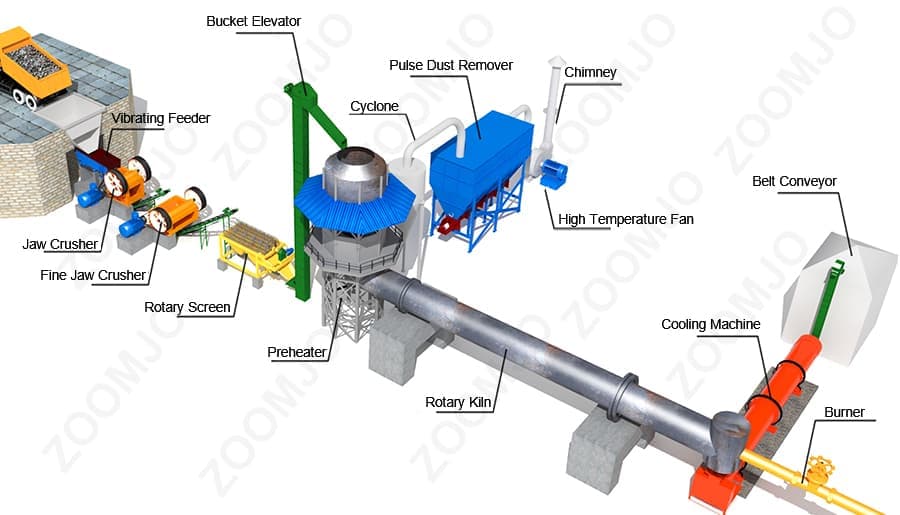

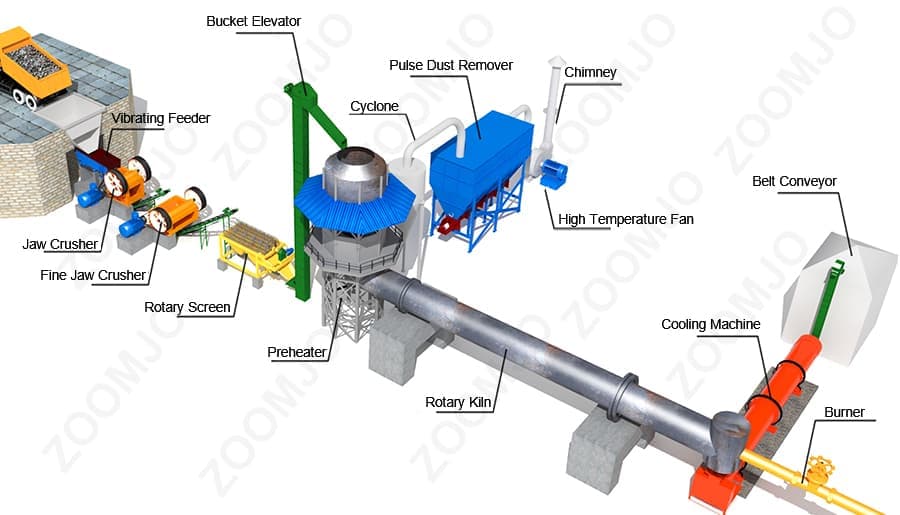

Metal Magnesium Rotary Kiln Product Description

our company professionally produces metal magnesium rotary kiln and its technics. The raw materials of technics are dolomite which is crushed to be certificated(30-40mm)by the crusher. And then the materials will be sintered by the rotary kiln until it becomes calcined dolomite and then they will be cooled by the cooling machine.

After that, the material will be milled by the ball mill and then press them into ball by pressing ball machine. After crushing , the ball will be made into dough by evenly mixing with ferrosilicon powder and fluorite powder. Putting them into stainless and heat-resisting steel reduction cylinder and make them be coarse magnesium under the temperature of 1200-1250 ℃ and 1.33 Pa vacuum degree.

Finally, the materials will be produced to magnesium ingot by fluxing, ingot casting and surface disposing.

Metal Magnesium Rotary Kiln Working Principle

1. Crushing the materials(dolomite) into certificated materials(30-40mm)

2. Burned by rotary into calcined dolomite

3. Cooled by the cooling machine

4. Milled into powder by the ball mill

5. Pressed into ball by pressing ball machine

6. Mixed evenly with ferrosilicon powder(including 75% of silicon) and fluorite powder(GaF2=95%)

7. Putting them into the stainless and heat-resisting steel reduction cylinder and be produced to magnesium ingot by fluxing, ingot casting and surface disposing.

Metal Magnesium Rotary Kiln Technical Parameter

Specification

(m) | Kiln Size | Power

(kw) | Wight

(t) | Remarks |

| Diameter(m) | Length(m) | Slope(%) | Capacity

(t/d) | Speed

(r/min) |

| Φ2.5×40 | 2.5 | 40 | 3.5 | 180 | 0.44-2.44 | 55 | 149.61 |

|

| Φ2.5×50 | 2.5 | 50 | 3 | 200 | 0.62-1.86 | 55 | 187.37 |

|

| Φ2.5×54 | 2.5 | 54 | 3.5 | 280 | 0.48-1.45 | 55 | 196.29 | Kiln decomposition kilns |

| Φ2.7×42 | 2.7 | 42 | 3.5 | 320 | 0.10-1.52 | 55 | 198.5 | ------ |

| Φ2.8×44 | 2.8 | 44 | 3.5 | 450 | 0.437-2.18 | 55 | 201.58 | Kiln decomposition kilns |

| Φ3.0×45 | 3 | 45 | 3.5 | 500 | 0.5-2.47 | 75 | 201.94 | ------ |

| Φ3.0×48 | 3 | 48 | 3.5 | 700 | 0.6-3.48 | 100 | 237 | Kiln decomposition kilns |

| Φ3.0×60 | 3 | 60 | 4 | 800 | 0.3-2 | 100 | 310 | ------ |

| Φ3.2×50 | 3.5 | 50 | 4 | 1000 | 0.6-3 | 125 | 278 | Kiln decomposition kilns |

| Φ3.3×52 | 3.3 | 52 | 3.5 | 1300 | 0.266-2.66 | 125 | 283 | Preheating decomposition kilns |

| Φ3.5×54 | 3.5 | 54 | 3.5 | 1500 | 0.55-3.4 | 220 | 363 | Preheating decomposition kilns |

| Φ3.6×70 | 3.6 | 70 | 3.5 | 1800 | 0.25-1.25 | 125 | 419 | Waste heat power kilns |

| Φ4.0×56 | 4 | 56 | 4 | 2300 | 0.41-4.07 | 315 | 456 | Preheating decomposition kilns |

| Φ4.0×60 | 4 | 60 | 3.5 | 2500 | 0.396-3.96 | 315 | 510 | Preheating decomposition kilns |

| Φ4.2×60 | 4.2 | 60 | 4 | 2750 | 0.41-4.07 | 375 | 633 | Preheating decomposition kilns |

| Φ4.3×60 | 4.3 | 60 | 3.5 | 3200 | 0.396-3.96 | 375 | 583 | Preheating decomposition kilns |

| Φ4.5×66 | 4.5 | 66 | 3.5 | 4000 | 0.41-4.1 | 560 | 710.4 | Preheating decomposition kilns |

| Φ4.7×74 | 4.7 | 74 | 4 | 4500 | 0.35-4 | 630 | 849 | Preheating decomposition kilns |

| Φ4.8×74 | 4.8 | 74 | 4 | 5000 | 0.396-3.96 | 630 | 899 | Preheating decomposition kilns |

| Φ5.0×74 | 5 | 74 | 4 | 6000 | 0.35-4 | 710 | 944 | Preheating decomposition kilns |

| Φ5.6×87 | 5.6 | 87 | 4 | 8000 | Max4.23 | 800 | 1265 | Preheating decomposition kilns |

| Φ6.0×95 | 6 | 95 | 4 | 10000 | Max5 | 950×2 | 1659 | Preheating decomposition kilns |