Water slag dryer Product Description

Water slag is a good raw material for cement, and the water slag dryer is an important industrial drying equipment using blast furnace water slag. The cover at both ends of the host machine is highly sealed, which is both energy-saving and environment-friendly. The power consumption is only 30% of that of similar products, and the coal consumption is only 50%.

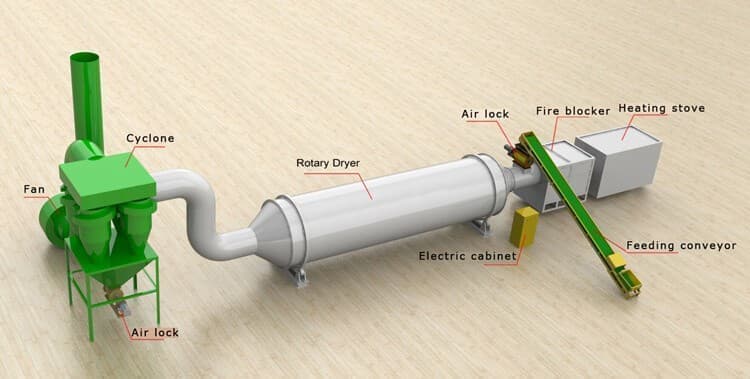

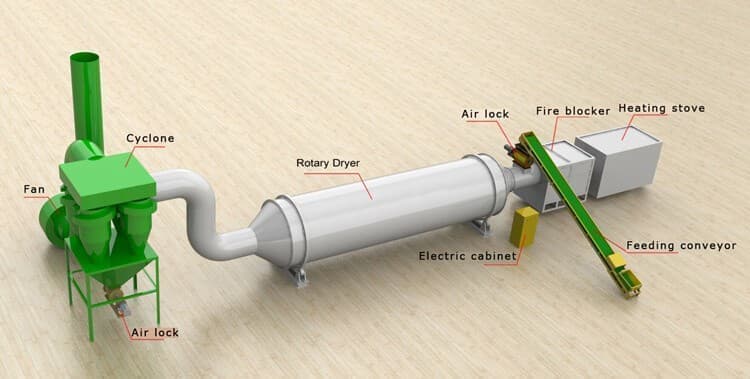

Water slag dryer is a rotary dryer, which is mainly composed of rotary cylinder, induced draft equipment, high-speed dispersing equipment, lifting plate, self-cleaning device, transmission device, conveying equipment, hot air equipment, reducer, support device, sealing device and other components. The water slag dryer is reasonably designed, well made, stable in performance, advanced in technology, high in output and low in energy consumption

Water slag dryer Working Principle

The water slag is sent to the hopper by the belt conveyor or bucket elevator, and then enters the feeding end through the feeding pipe through the feeder of the hopper. The inclination of the feeding pipe shall be greater than the natural inclination of the material, so that the material can flow smoothly into the mine dryer. The dryer cylinder is a rotating cylinder slightly inclined to the horizontal line. The material is added from the higher end, and the heat carrier enters from the lower end, making countercurrent contact with the material.

Some heat carriers and materials flow into the cylinder together. With the rotation of the cylinder, the material moves to the lower end under the action of gravity. In the process of moving forward in the cylinder, the wet material is directly or indirectly supplied by the heat carrier, which makes the wet material dry, and then sent out through the belt conveyor or screw conveyor at the discharge end. The inner wall of the water slag dryer cylinder is equipped with a board, which is used to copy and scatter the materials, so as to increase the contact surface between the materials and the air flow, so as to improve the drying rate and promote the advance of the materials.

Water slag dryer Features And Advantages

1. With advanced technical parameters, the production capacity is stronger, the structure is more scientific and novel, and the drying capacity and efficiency are high.

2. The roller is used to transmit power when the cylinder rotates, so that the service life of the equipment is longer. The cylinder is equipped with a device to prevent blocking.

3. The use of thermal insulation, fully enclosed operating environment, so that the production of equipment is more safe and convenient.

4. The materials that can be operated include: waste slag, cinder, slag and other powder, block and particle shaped materials produced by various iron and steel plants.

Water slag dryer Technical Parameter

specs(m)

(diameter × length) | Cylinder volume

(m³) | throughput

(t/h) | Slope

(%) | air temperature

(℃) | Main motor

(kw) | Total weight

(t) |

| Φ1.2×8.0 | 9.0 | 1.9-2.4 | 3-5 | 700-800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4-3.0 | 3-5 | 700-800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5-5.7 | 3-5 | 700-800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3-6.6 | 3-5 | 700-800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7-7.1 | 3-5 | 700-800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5-8.1 | 3-5 | 700-800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6-9.5 | 3-5 | 700-800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7-12.2 | 3-5 | 700-800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4-14.2 | 3-5 | 700-800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0-16.2 | 3-5 | 700-800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5-16.9 | 3-5 | 700-800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4-21.7 | 3-5 | 700-800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3-24.1 | 3-5 | 700-800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2-26.5 | 3-5 | 700-800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2-34.0 | 3-5 | 700-800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1-37.7 | 3-5 | 700-800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7-47.1 | 3-5 | 700-800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9-53.6 | 3-5 | 700-800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8-76.0 | 3-5 | 700-800 | 160 | 135 |