Ceramic Granule Rotary Kiln Product Description

Ceramic sand rotary kiln is the working temperature can reach (950 ℃ ~ 1050 ℃) calcination of ultra-fine kaolin process. At present, our technology has matured and represents the development direction of ultra-fine kaolin calcination technology. This calcination technology has low energy consumption, high yield, and the product is dehydrated, decarbonised and whitened, with stable performance, and can be used in industrial fields such as paper and paint.

Ceramic pellet rotary kiln is widely used in the calcination and production of various materials such as dolomite, kaolin, bauxite, refractory furnace material, cement, limestone, titanium iron powder, alum ore, activated carbon, coke, mineral powder, alumina, magnesium oxide, zinc oxide, special cement and other ceramic pellets.

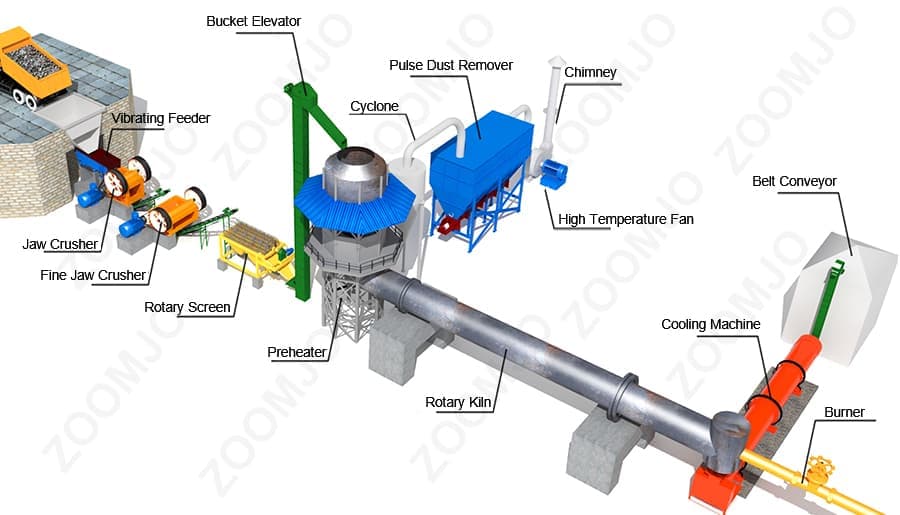

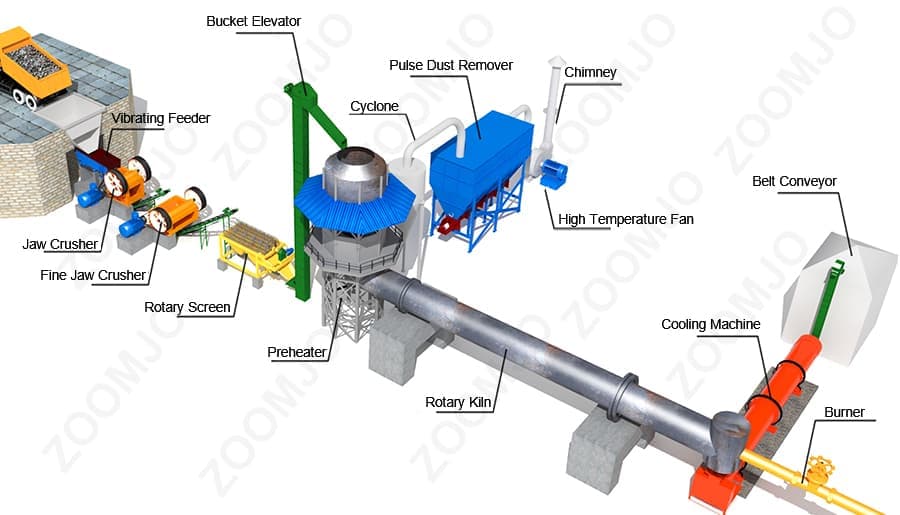

Ceramic Granule Rotary Kiln Working Principle

The structure and working principle of Ceramic Granule Rotary Kiln:

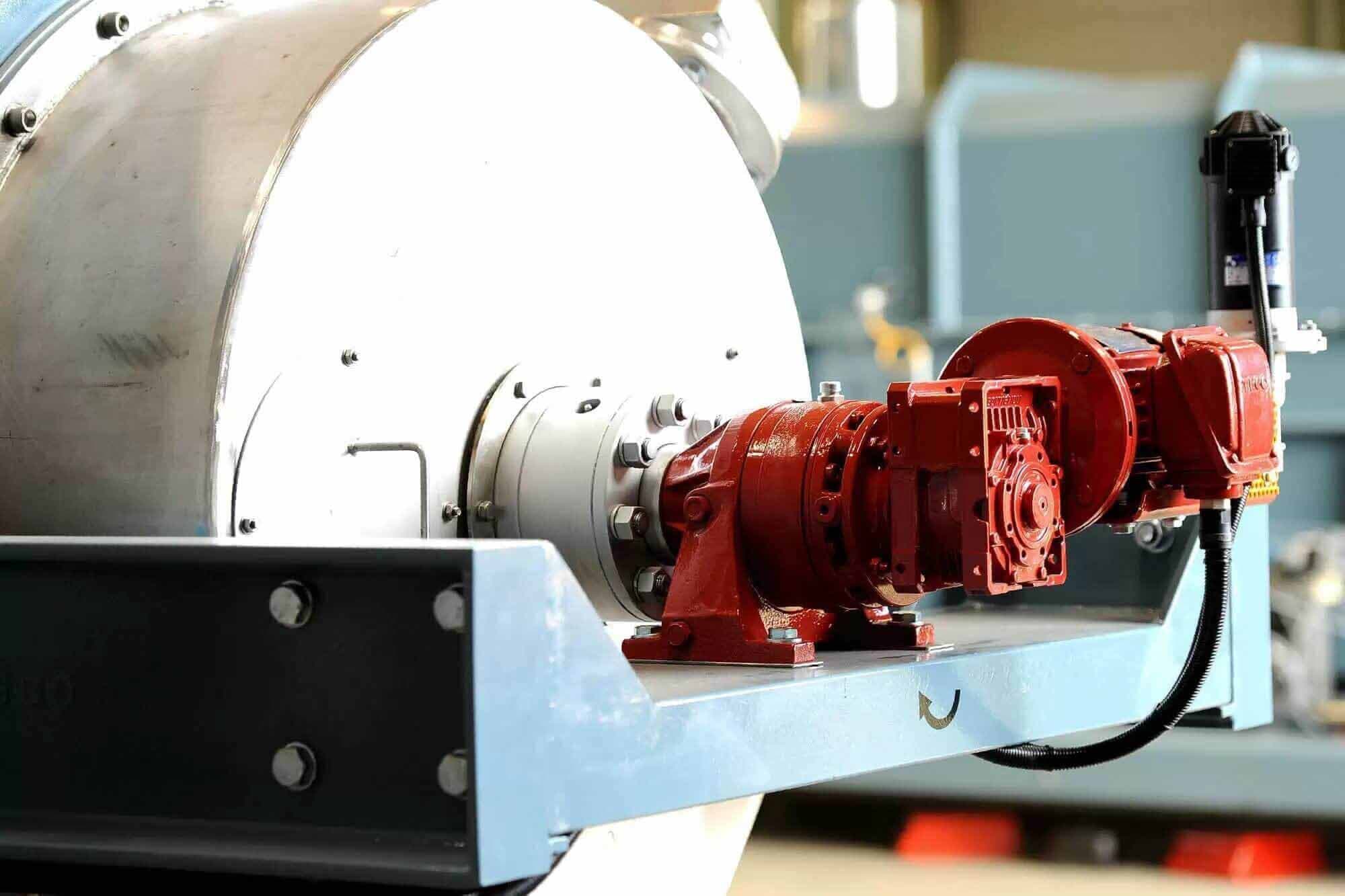

First, ceramic granule rotary kiln consist of the rotary kiln body, support device, kiln head and stern sealing device, pulverized coal injection pipe device etc.

Second, between the kiln body and horizontal have an angle, the whole kiln body's round by supporting device, and has a catch wheel device controls the kiln body move up and down.

Third, transmission parts in addition to set the main transmission but also set up auxiliary transmission device which can ensure still supply power make the kiln body rotated slowly when the main transmission is not work. This can prevent the kiln body deformation . Kiln head adopts shell prover seal ,guarantee the reliability of the seal.

Ceramic Granule Rotary Kiln Features And Advantages

1, simple structure, long service life, high rates, stable operation, high heat transfer efficiency, low heat consumption,

2, temperature automatic control, super temperature alarming, two times wind waste heat utilization, long service life kiln lining,

3, advanced kiln head sealing technology, stable operation, high output and other notable features.

Ceramic Granule Rotary Kiln Technical Parameter

Specification

(m) | Kiln Size | Power

(kw) | Wight

(t) | Remarks |

| Diameter(m) | Length(m) | Slope(%) | Capacity

(t/d) | Speed

(r/min) |

| Φ2.5×40 | 2.5 | 40 | 3.5 | 180 | 0.44-2.44 | 55 | 149.61 |

|

| Φ2.5×50 | 2.5 | 50 | 3 | 200 | 0.62-1.86 | 55 | 187.37 |

|

| Φ2.5×54 | 2.5 | 54 | 3.5 | 280 | 0.48-1.45 | 55 | 196.29 | Kiln decomposition kilns |

| Φ2.7×42 | 2.7 | 42 | 3.5 | 320 | 0.10-1.52 | 55 | 198.5 | ------ |

| Φ2.8×44 | 2.8 | 44 | 3.5 | 450 | 0.437-2.18 | 55 | 201.58 | Kiln decomposition kilns |

| Φ3.0×45 | 3 | 45 | 3.5 | 500 | 0.5-2.47 | 75 | 201.94 | ------ |

| Φ3.0×48 | 3 | 48 | 3.5 | 700 | 0.6-3.48 | 100 | 237 | Kiln decomposition kilns |

| Φ3.0×60 | 3 | 60 | 4 | 800 | 0.3-2 | 100 | 310 | ------ |

| Φ3.2×50 | 3.5 | 50 | 4 | 1000 | 0.6-3 | 125 | 278 | Kiln decomposition kilns |

| Φ3.3×52 | 3.3 | 52 | 3.5 | 1300 | 0.266-2.66 | 125 | 283 | Preheating decomposition kilns |

| Φ3.5×54 | 3.5 | 54 | 3.5 | 1500 | 0.55-3.4 | 220 | 363 | Preheating decomposition kilns |

| Φ3.6×70 | 3.6 | 70 | 3.5 | 1800 | 0.25-1.25 | 125 | 419 | Waste heat power kilns |

| Φ4.0×56 | 4 | 56 | 4 | 2300 | 0.41-4.07 | 315 | 456 | Preheating decomposition kilns |

| Φ4.0×60 | 4 | 60 | 3.5 | 2500 | 0.396-3.96 | 315 | 510 | Preheating decomposition kilns |

| Φ4.2×60 | 4.2 | 60 | 4 | 2750 | 0.41-4.07 | 375 | 633 | Preheating decomposition kilns |

| Φ4.3×60 | 4.3 | 60 | 3.5 | 3200 | 0.396-3.96 | 375 | 583 | Preheating decomposition kilns |

| Φ4.5×66 | 4.5 | 66 | 3.5 | 4000 | 0.41-4.1 | 560 | 710.4 | Preheating decomposition kilns |

| Φ4.7×74 | 4.7 | 74 | 4 | 4500 | 0.35-4 | 630 | 849 | Preheating decomposition kilns |

| Φ4.8×74 | 4.8 | 74 | 4 | 5000 | 0.396-3.96 | 630 | 899 | Preheating decomposition kilns |

| Φ5.0×74 | 5 | 74 | 4 | 6000 | 0.35-4 | 710 | 944 | Preheating decomposition kilns |

| Φ5.6×87 | 5.6 | 87 | 4 | 8000 | Max4.23 | 800 | 1265 | Preheating decomposition kilns |

| Φ6.0×95 | 6 | 95 | 4 | 10000 | Max5 | 950×2 | 1659 | Preheating decomposition kilns |