Slag dryer Product Description

Like ordinary dryers, slag dryers can be used to dry slag produced after smelting in iron and steel plants, as well as carbide slag, limestone, clay, river sand, quartz sand, water slag and other materials. There are many names of dryers according to different drying materials.

For example, metal powder dryer can be called for drying metal powder, and iron concentrate pellet dryer can be called for drying iron concentrate pellets.

Slag dryer Working Principle

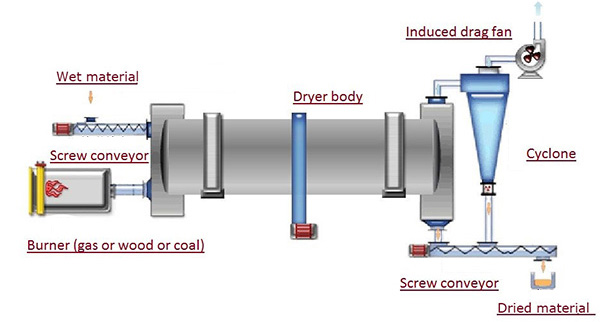

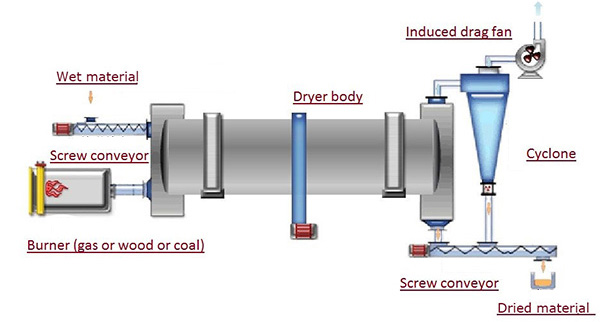

Slag dryer structure is composed of rotary body, lifting plate, transmission device, support device, sealing ring and other components. The rotary body in the iron slag dryer is the main part of the dryer, which can also be called the drying cylinder. The part is a rotating cylinder slightly inclined to the horizontal line.

During the drying operation, the materials are added from the higher end, and the heat carrier enters from the lower end, making countercurrent contact with the materials. Some heat carriers and materials flow into the cylinder together. With the rotation of the cylinder, the material moves to the lower end under the action of gravity. When the wet material moves forward in the cylinder, it is directly or indirectly supplied by the heat carrier, which makes the wet material dry.

Slag dryer Features And Advantages

The slag dryer is simple in structure and technology and reasonable in configuration. The equipment is mainly composed of cylinder, feed chute, lifting plate, reducer, gear, roll ring, motor, discharge department and other components. The equipment operates efficiently and stably with good use effect.

The slag dryer, metal powder dryer, iron concentrate pellet dryer and other series of drying equipment produced by our company are reasonably designed, well made, stable in performance, high in process technology, high in output, low in energy consumption, small in floor area, high in mechanization, and highly expandable. They can be used to dry slag, iron concentrate pellets, metal powder, fly ash, lignite and other wet materials to meet most customer needs.

Slag dryer Technical Parameter

specs(m)

(diameter × length) | Cylinder volume

(m³) | throughput

(t/h) | Slope

(%) | air temperature

(℃) | Main motor

(kw) | Total weight

(t) |

| Φ1.2×8.0 | 9.0 | 1.9-2.4 | 3-5 | 700-800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4-3.0 | 3-5 | 700-800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5-5.7 | 3-5 | 700-800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3-6.6 | 3-5 | 700-800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7-7.1 | 3-5 | 700-800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5-8.1 | 3-5 | 700-800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6-9.5 | 3-5 | 700-800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7-12.2 | 3-5 | 700-800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4-14.2 | 3-5 | 700-800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0-16.2 | 3-5 | 700-800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5-16.9 | 3-5 | 700-800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4-21.7 | 3-5 | 700-800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3-24.1 | 3-5 | 700-800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2-26.5 | 3-5 | 700-800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2-34.0 | 3-5 | 700-800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1-37.7 | 3-5 | 700-800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7-47.1 | 3-5 | 700-800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9-53.6 | 3-5 | 700-800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8-76.0 | 3-5 | 700-800 | 160 | 135 |