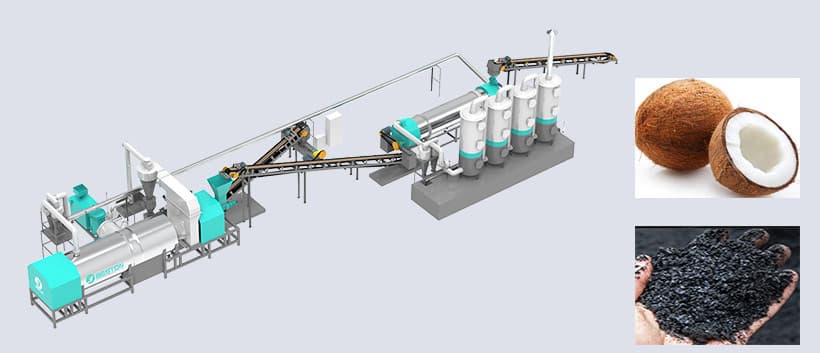

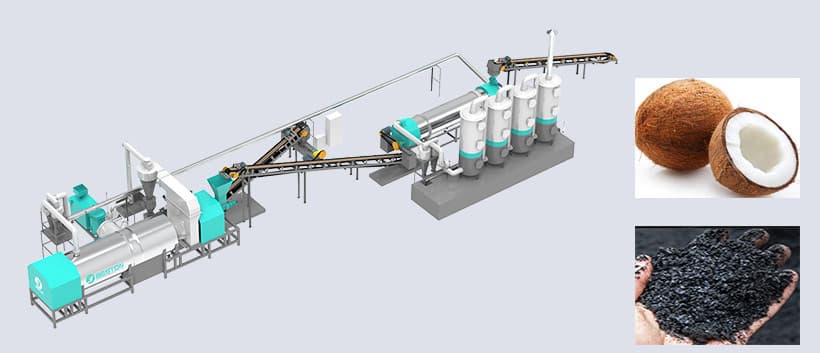

Coco peat Dryer Product Description

Coconut peat is coconut husk fibre powder, which is a by-product or waste from the processing of coconuts. Once dried, coconut peat can be used in the field of plant cultivation or made into coir bricks with a high economic benefit. Processed coconut husk peat is very suitable for cultivating plants and is now a popular horticultural medium. It is widely used worldwide and is a nature and environmentally friendly product that developed countries are committed to promoting. Coconut peat is compressed for small storage space and easy transportation, which greatly reduces the cost of storage and transportation. As a result, the market for coconut peat dryers is promising and in high demand.

The coconut peat drying system has the advantage of energy saving and low consumption technology. With precise temperature control and scientific sealing technology, the production process is safe, efficient, clean and environmentally friendly.

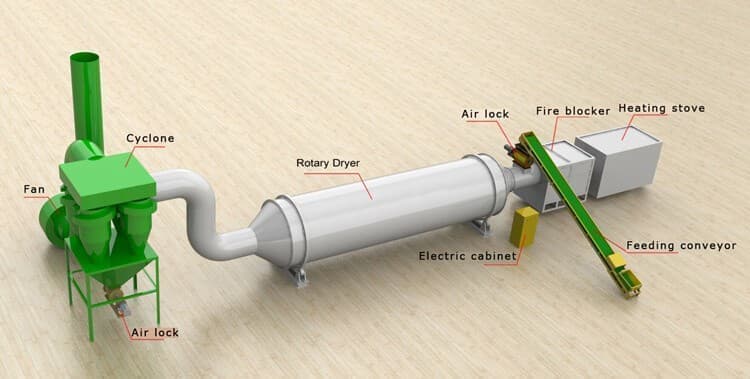

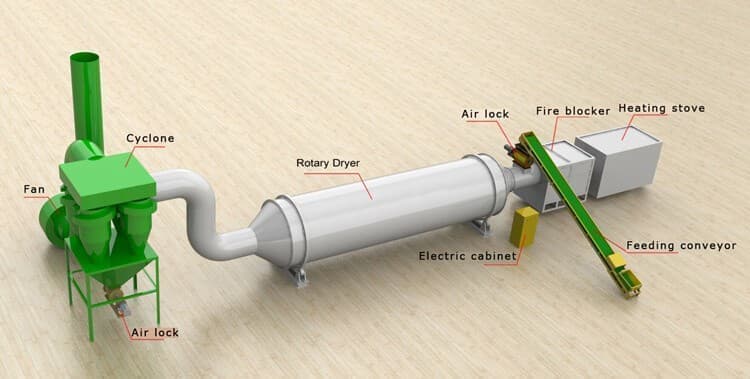

First, the coconut peat is dewatered through a dewatering machine (if the moisture content is high) and then transported via a belt conveyor to a drum dryer. Due to the inclination of the drum dryer, the material with hot air moves to the end of the main body of the dryer, where the wet material comes into full contact with the hot air in the process. After drying, the majority of the dry material is discharged via a belt conveyor. The remaining material is mixed with dust and continues in turn into the cyclone and baghouse where the dust will be collected. Finally, the remaining material will be discharged via the conveyor under the action of the induced draft fan.

Coco peat Dryer Working Principle

Coconut husk process: after desalination and dehydration 50-60% moisture coconut husk is sent into the dryer to achieve flow drying, coconut husk is constantly lifted and lowered on the shovel plate inside the dryer, spiral forward, through the inner, middle and outer layers of the dryer, coconut husk is heat exchanged with hot air, the dried coconut husk is moved quickly by the wind and discharged, wet coconut husk cannot move quickly because of its own weight. The coconut husk is fully dried in the dryer and the moisture is reduced to 14-18% (can be adjusted according to customer requirements), after the drying process the husk will be discharged by the screw conveyor. There is a special device inside the dryer which prevents uneven drying of the coconut shells.

Hot air process: Our dryer is equipped with an energy efficient hot air oven, the fuel can be natural gas, diesel, coal, wood, straw, rice husk, etc.. It will provide oxygen-poor hot air at 500-650°C. After settling and ash removal, it will enter the dryer, which will then evaporate the moisture and dry the coconut palm, and the hot air temperature will be reduced to 50-65°C when discharged from the dryer. The wet and dust laden exhaust air will pass through a specialist dust collector and can then be brought up to emission standards.

Coco peat Dryer Features And Advantages

1. Automatic control ensures a homogeneous and stable drying process.

2. Internal structure designed for coconut peat. Drying efficiency of up to 90-95%.

3. Customised solutions. Variation of the operating parameters according to the properties of the required parameters.

4. Designed lifting plates. Various materials are lifted using various combinations of circles.

5. System equipped with PLC system and video monitoring system for high automation and easy operation.

6. Multiple heating sources. Customers can choose the heating source according to their situation and we can design customised solutions.

7. Supplied with accessories. The quality of accessories is guaranteed.

Coco peat Dryer Technical Parameter

|

Item | ZJ25-A |

ZJ25-B |

ZJ30-A |

ZJ30-B |

ZJ30-C |

ZJ36-A |

ZJ36-B |

ZJ36-C |

ZJ42-A |

ZJ42-B |

|

Diameter (mm) |

2500 |

2500 |

3000 |

3000 |

3000 |

3600 |

3600 |

3600 |

4200 |

4200 |

|

Length (mm) |

8000 |

10500 |

10500 |

13000 |

15500 |

13000 |

15500 |

18500 |

15500 |

18500 |

|

Capacity (t/h) |

2 |

3 |

4.5 |

5.5 |

6.5 |

9 |

10 |

12 |

13.5 |

16.8 |

|

Drying Type |

Three pass drum dryer |

|

Note |

Proper models can be customized according to your demands. Please feel free to contact with us any time! |