Malay coconut palm shred dryer runs smoothly

【Production capacity】: 0.3-5t/h

【Loading power】: 20-75kw

【Feeding moisture】: 45-55%

【Applicable materials】: Mainly suitable for drying coconut silk, palm silk, coconut fiber, palm fiber and other light fiber materials.

The biomass fibre drying system is suitable for drying light fibre materials such as coir, palm shreds, coir fibres and palm fibres. The advantages of the new biomass fibre dryer are mainly focused on the principle that it is optimised for fibre materials.

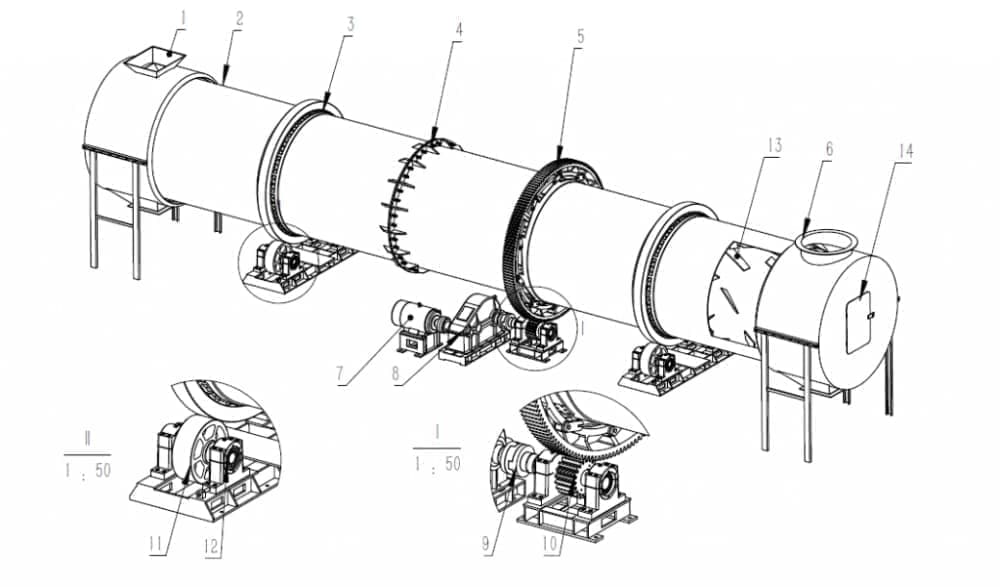

The shredded coconut palm dryer combines the principle of a drum dryer + sifter + carding equipment. The fresh fruit enters the rotary drum inlet after the filament has been opened and dries while in slow motion, with the hot air coming into contact with the material in the first half in downstream for fast dehydration and in the second half against the flow to achieve the desired drying effect. At the same time, the internal structural parts that push the filament movement are different from the ordinary lifting plate, which is designed for filament materials, with small fragmentation and good combing effect, and is widely praised by customers.

The biomass fibre drying system adopts new drying technology and is specially designed for long fibre biomass raw materials, which can meet the customer's expectation of dewatering and drying and reprocessing of fibre materials that are difficult to be dried by ordinary drying equipment such as coconut silk and palm silk. The system is safe, intelligent, energy saving, environmental friendly, efficient and highly productive. In addition to the drying technology for coconut shredded materials, TIDE can also provide a full set of solutions for opening, crushing, carbonisation, activation, granulation and palletising to meet the customised needs of different customers.

The dryer can quickly dry silk fibres with a moisture content of 30%-45% to a finished product with a moisture content of less than 18%. In addition to using traditional energy sources such as coal, oil, gas and electric heat, the dryer can also use wood, straw, shells and other waste as energy sources, recycling waste and reducing operating costs.